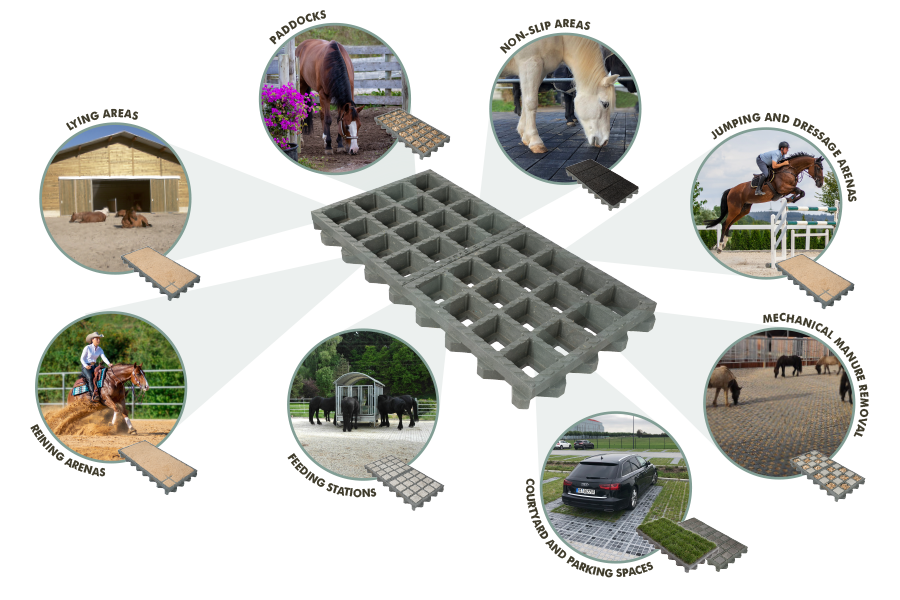

TTE® System

The ecological multi-talent for

equestrian sports and animal husbandry

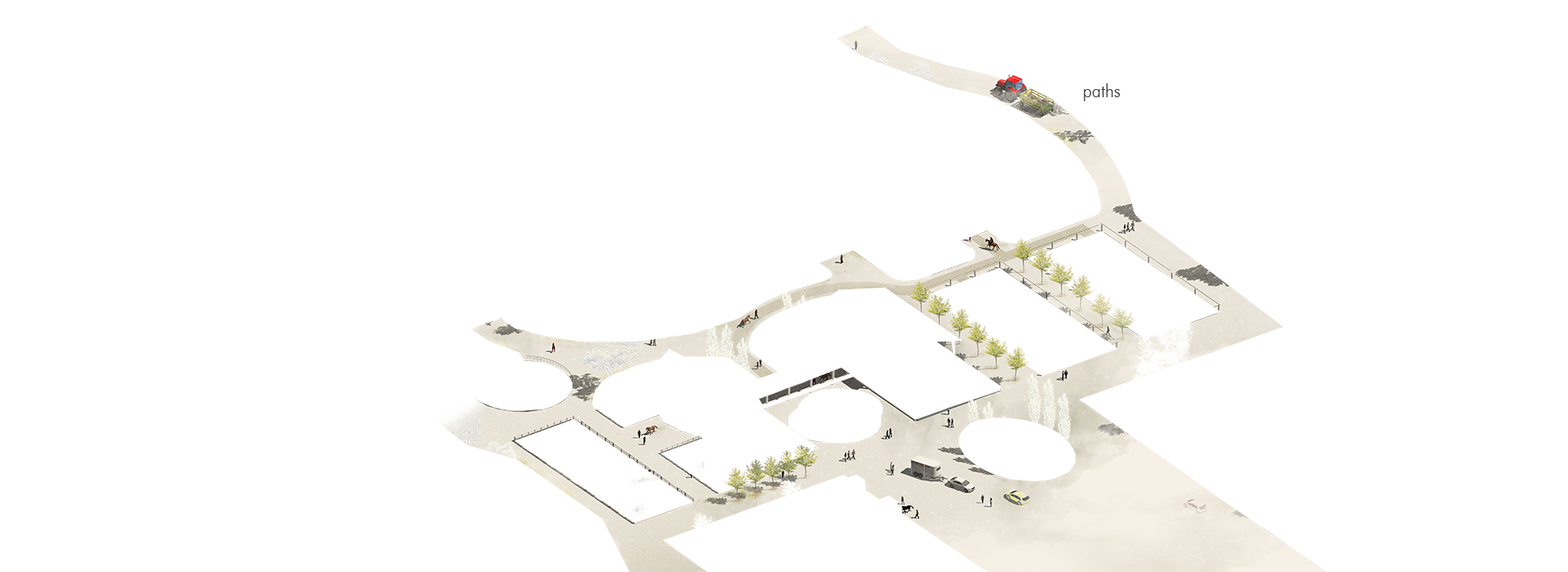

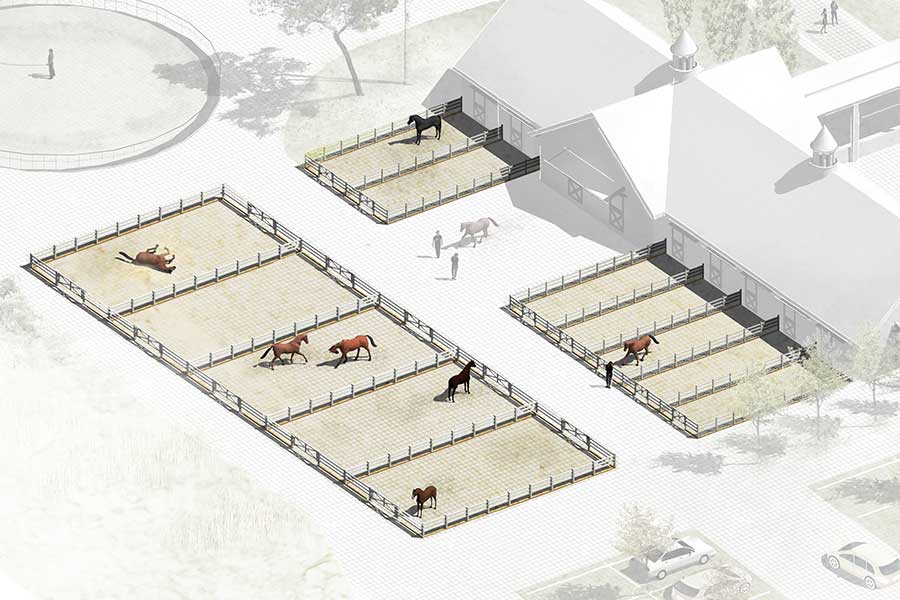

The TTE® system makes it easy for you to build your equestrian areas.

Due to the different fillings and construction principles you can use TTE® MultidrainPLUS to pave all areas of your equestrian facility - completely without a substructure.

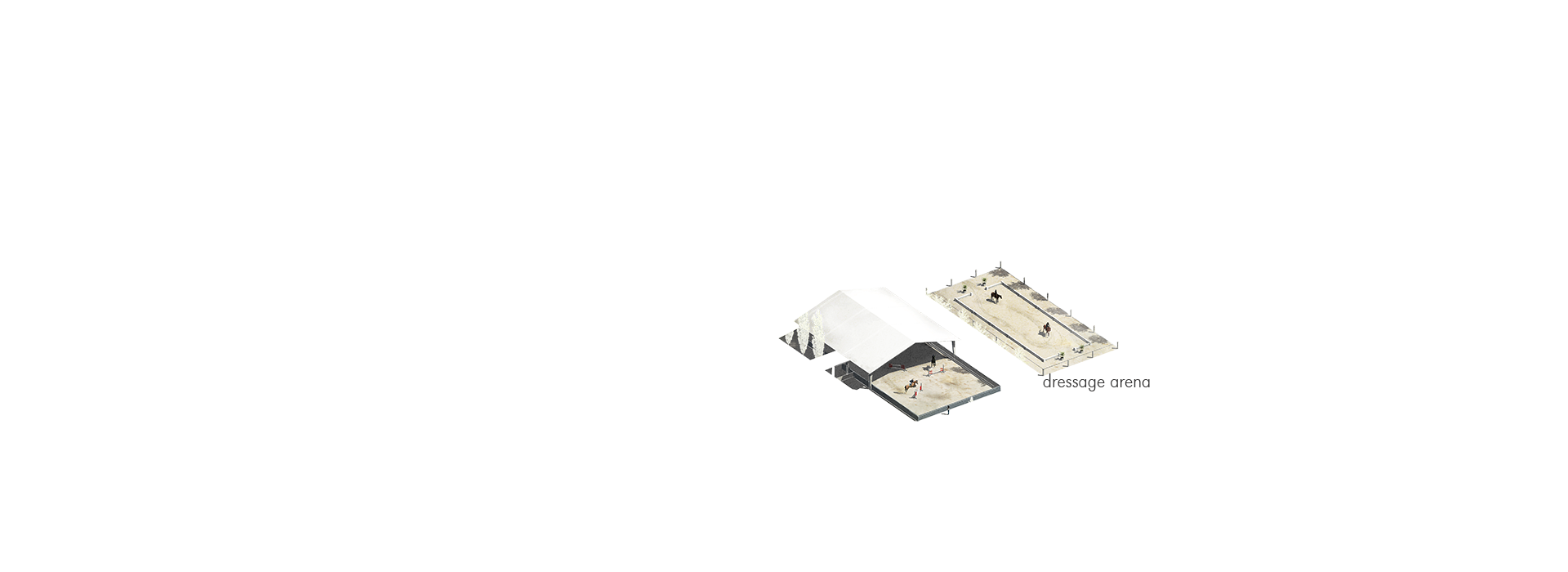

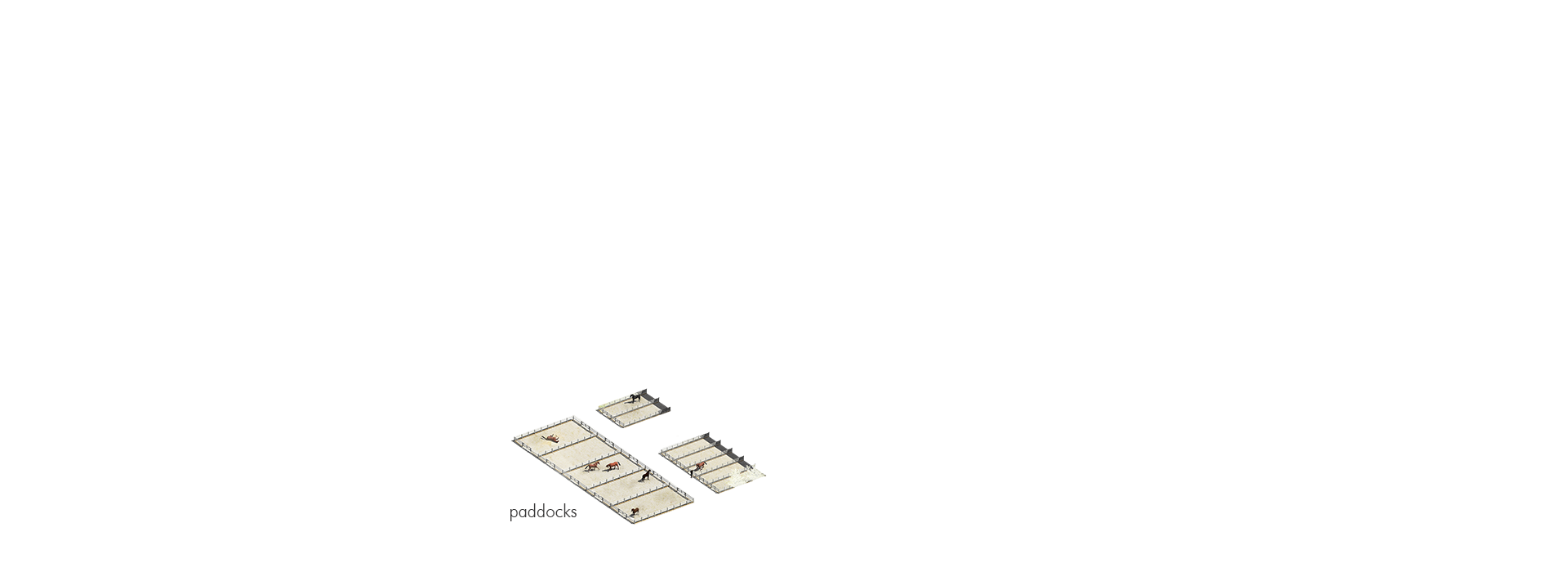

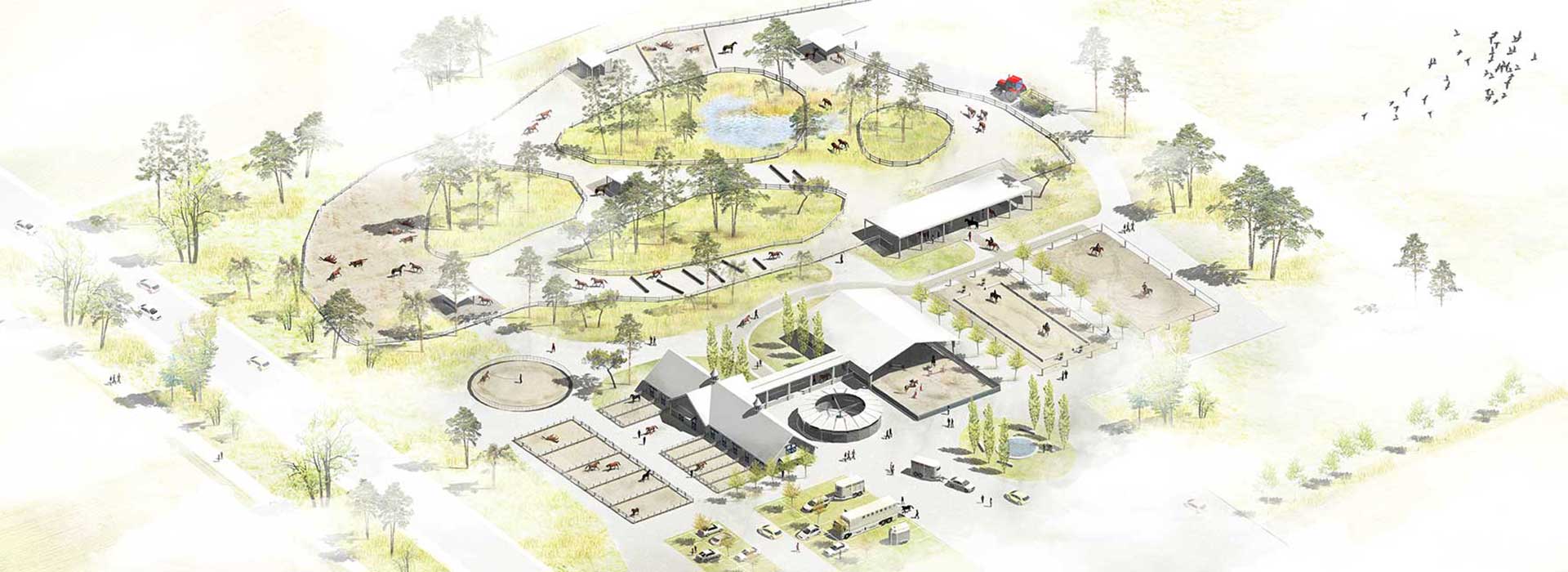

No matter whether it's a paddock, jumping or dressage arena, lying area or yard and parking areas: Thanks to the different filling variants, you can easily meet all your needs and the needs of your horses.

Due to the different fillings and construction principles you can use TTE® MultidrainPLUS to pave all areas of your equestrian facility - completely without a substructure.

No matter whether it's a paddock, jumping or dressage arena, lying area or yard and parking areas: Thanks to the different filling variants, you can easily meet all your needs and the needs of your horses.

TTE® - the multi-talent of surface paving for your equestrian facility

TTE® MultidrainPLUS

The robust paddock grid

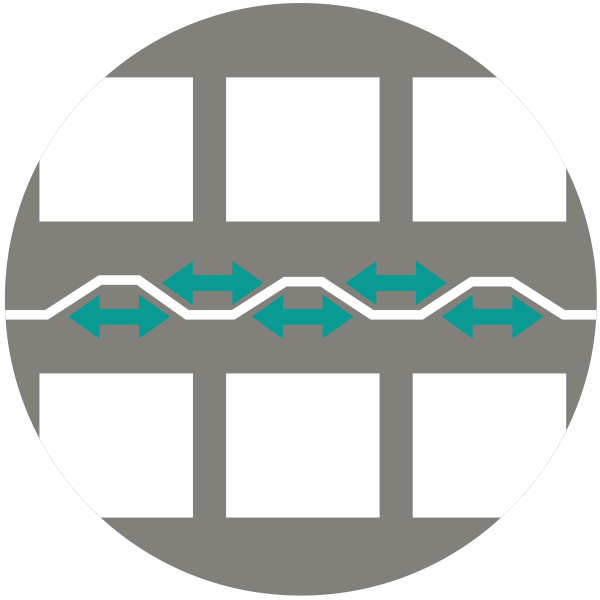

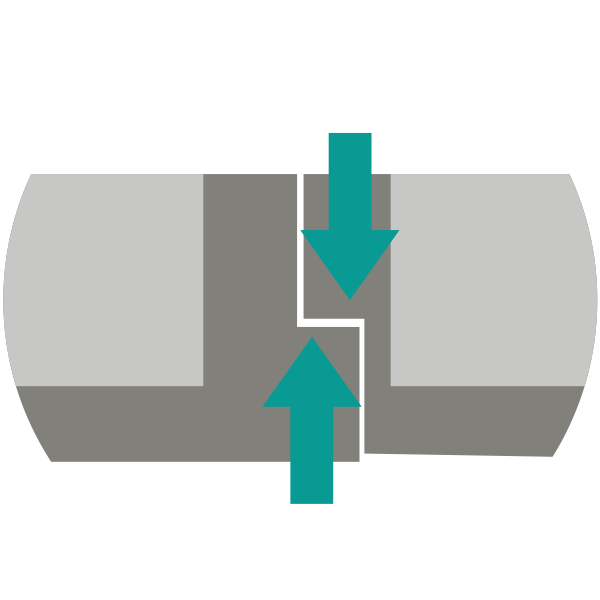

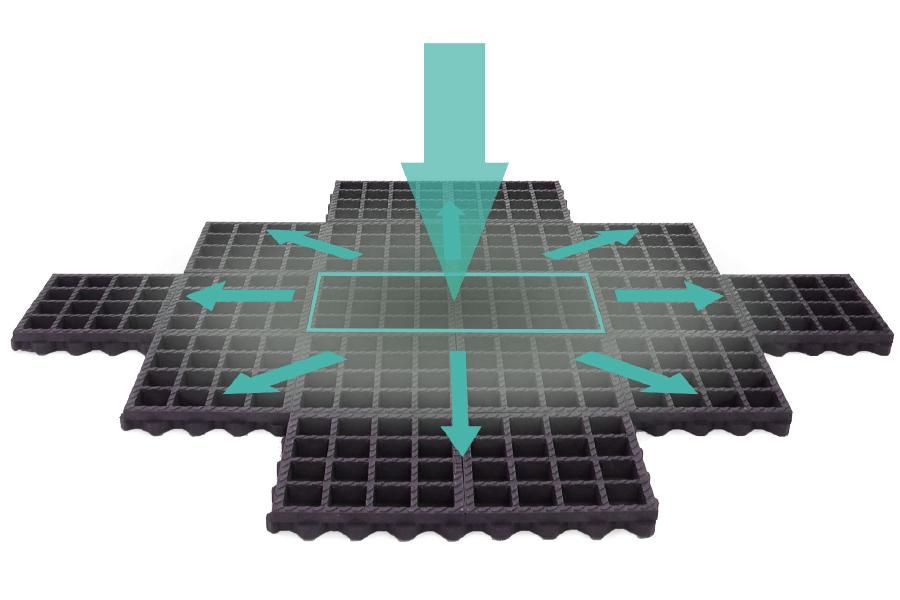

The TTE® paddock panels are connected horizontally and vertically with the aid of solid pins. It is not possible to break off individual paddock plates. In addition, the 2:1 format and a total weight of 27 kg/m², in combination with the intelligent bond, create an extremely load-bearing snowshoe effect.

This enables load distribution over a wide area, allowing paddocks, riding arenas and exercise areas to be built easily and made level without a substructure.

This enables load distribution over a wide area, allowing paddocks, riding arenas and exercise areas to be built easily and made level without a substructure.

Top and bottom view of TTE®

80 x 40 x 6 cm

Dimensions

27 kg per square metre

8.7 kg per plate

Weight

8.7 kg per plate

Weight

inner: 15 mm

outer: 20 mm

Fin width

outer: 20 mm

Fin width

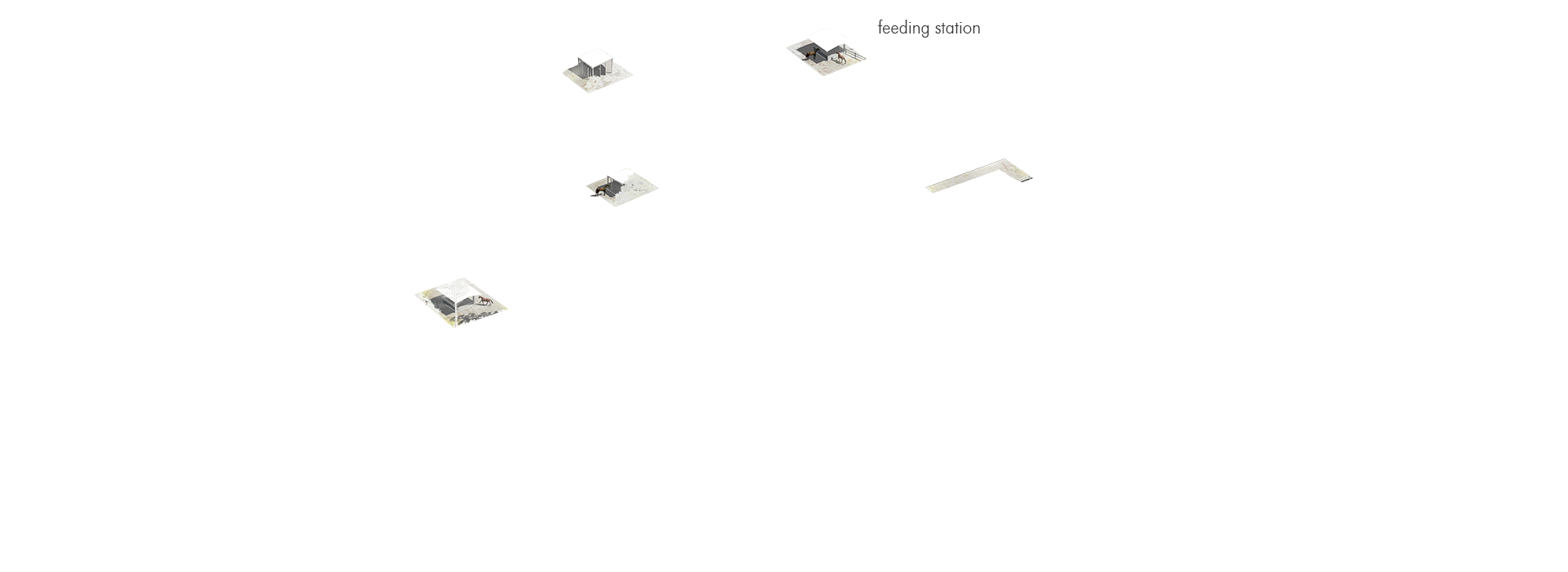

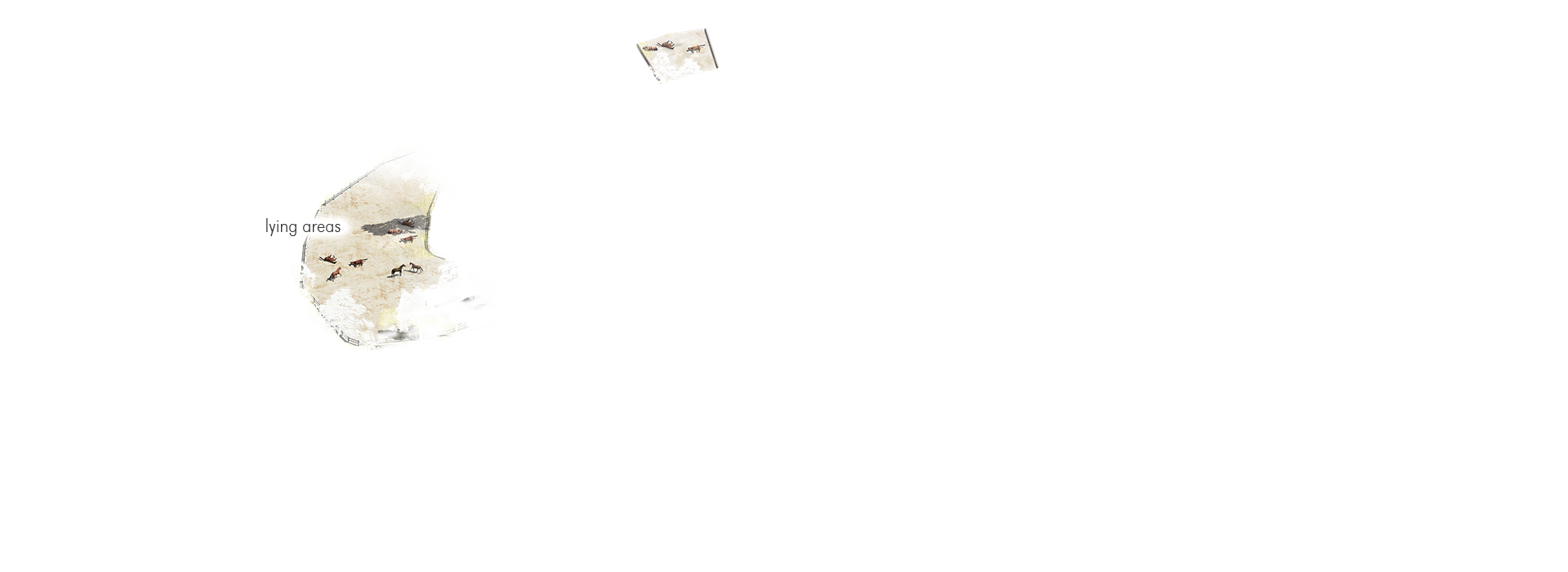

TTE® MultidrainPLUS -

Areas of application

Paddocks/Enclosures

Dressage and jumping arenas

Reining arena

Horse walker

Lunge pen

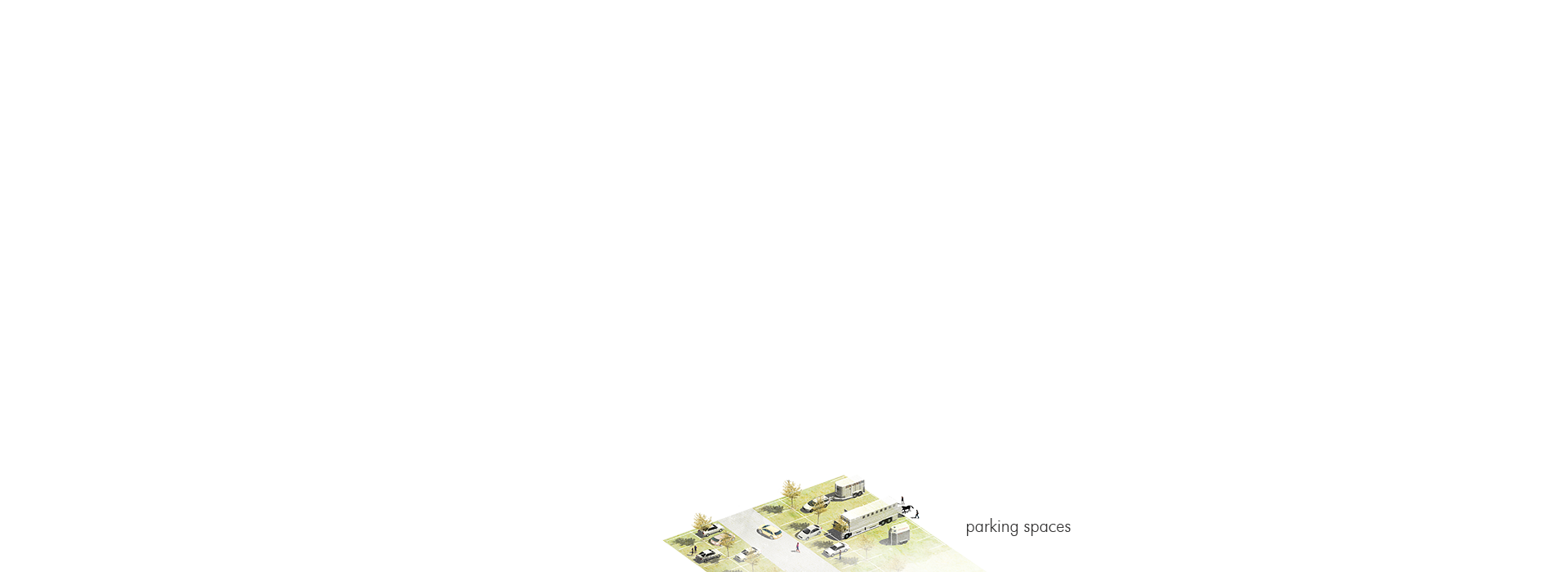

Parking spaces