CC Trolley Tracks

For CC containers, Danish trolleys and transport carts

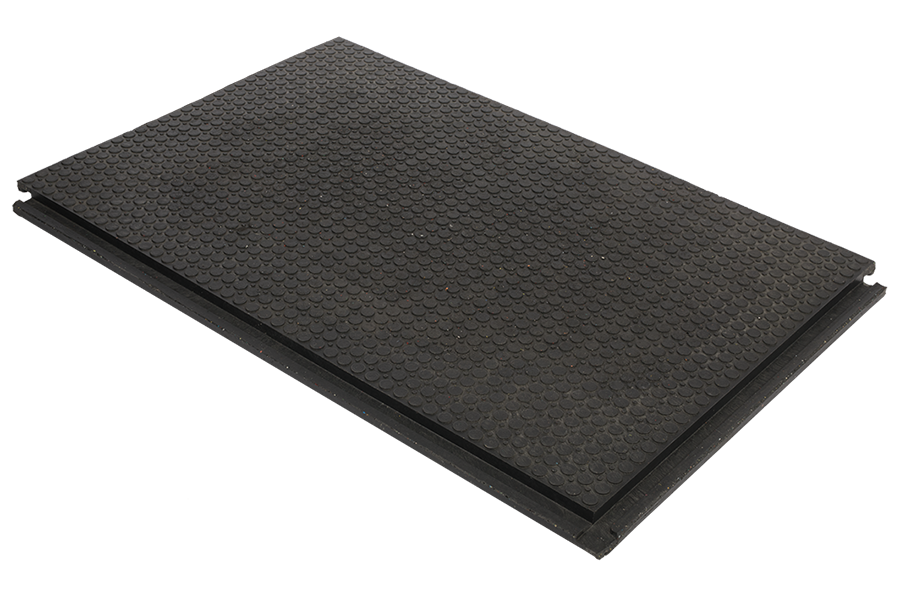

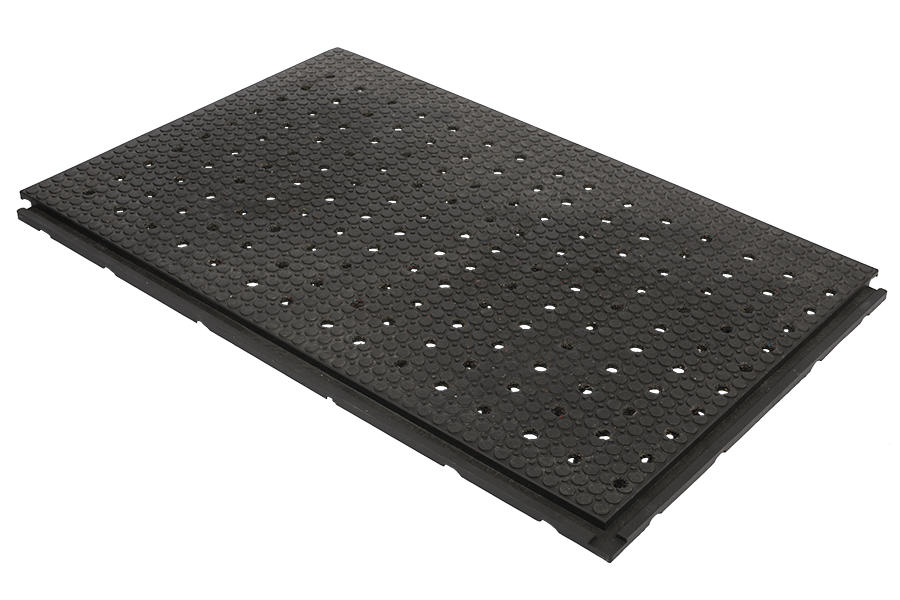

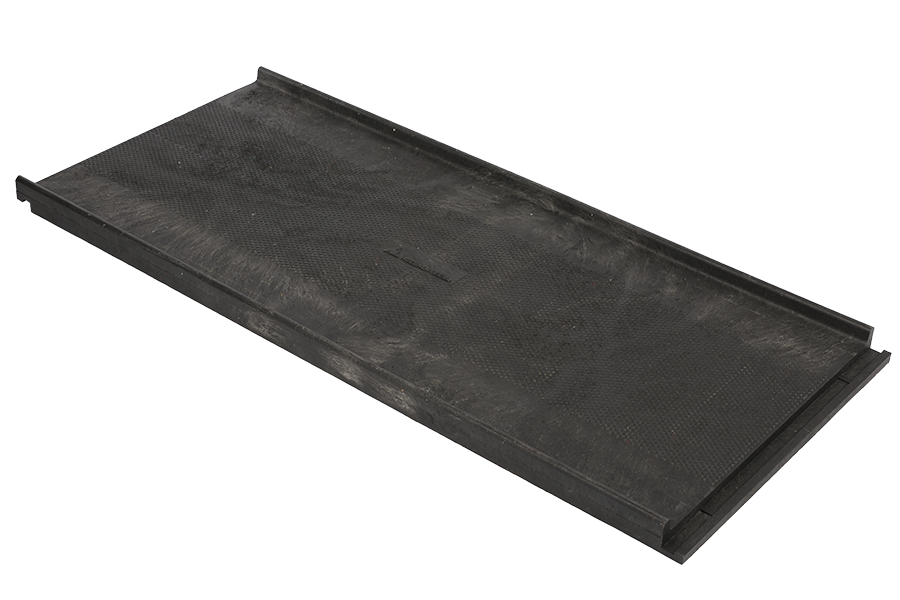

A practical road plate made of smooth-running plastic – that is the idea behind the CC Trolley Track. It serves as a pavement slab for staff and customers or as a wheel guiding system for CC trolleys and transport carts and can be laid extremely easily.

Manufactured entirely from recycled post-consumer cable sheathing

The practical alternative to concrete slabs

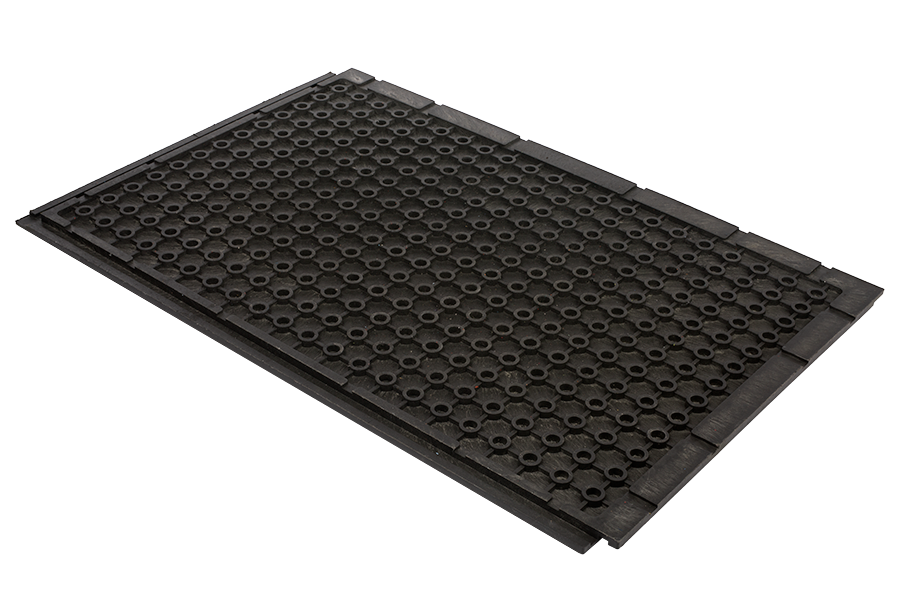

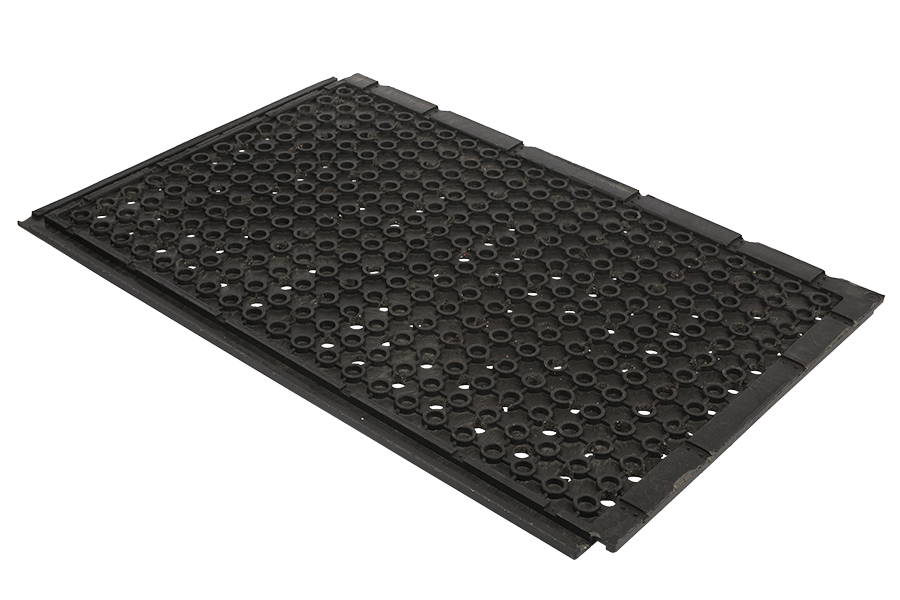

with integrated wheel guides

The idea is a practical trolley track made of smooth-running plastic. It serves as a walkway plate for customers, or as a sliding surface for CC trolleys or transport carts. The plastic plate is extremely easy to lay.

Furthermore, the surface this solution is laid on does not have to fulfil any special requirements, making it a high-quality alternative to concrete path slabs. The material used is characterised by durability, elasticity, noise insulation and weather resistance. Its low weight of 18 kg allows you to lay the trolley tracks by hand or move the ground plates to adapt to changes in logistics paths – a real challenge when using concrete slabs.

Furthermore, the surface this solution is laid on does not have to fulfil any special requirements, making it a high-quality alternative to concrete path slabs. The material used is characterised by durability, elasticity, noise insulation and weather resistance. Its low weight of 18 kg allows you to lay the trolley tracks by hand or move the ground plates to adapt to changes in logistics paths – a real challenge when using concrete slabs.

CC Trolley Tracks in use

Alternative to concrete slabs

with impressive advantages

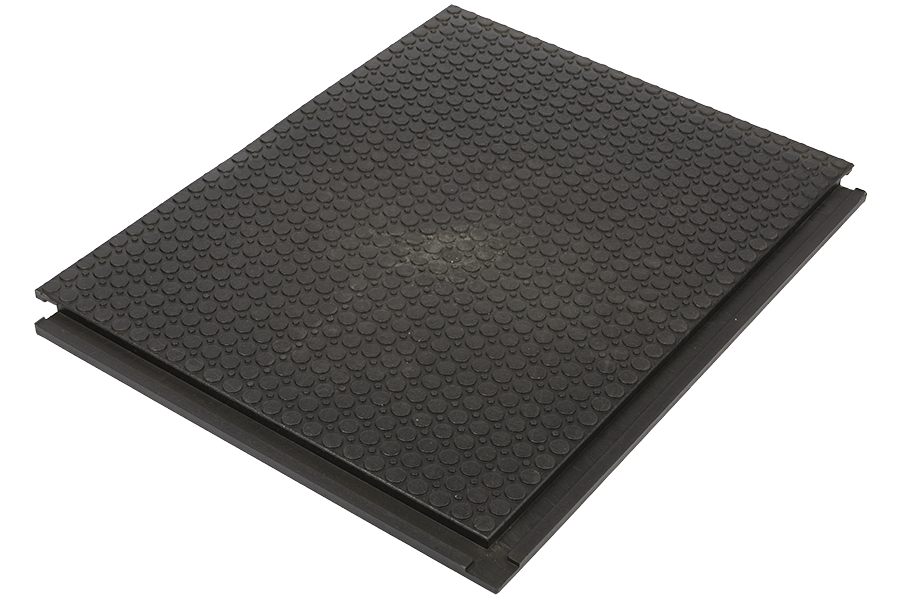

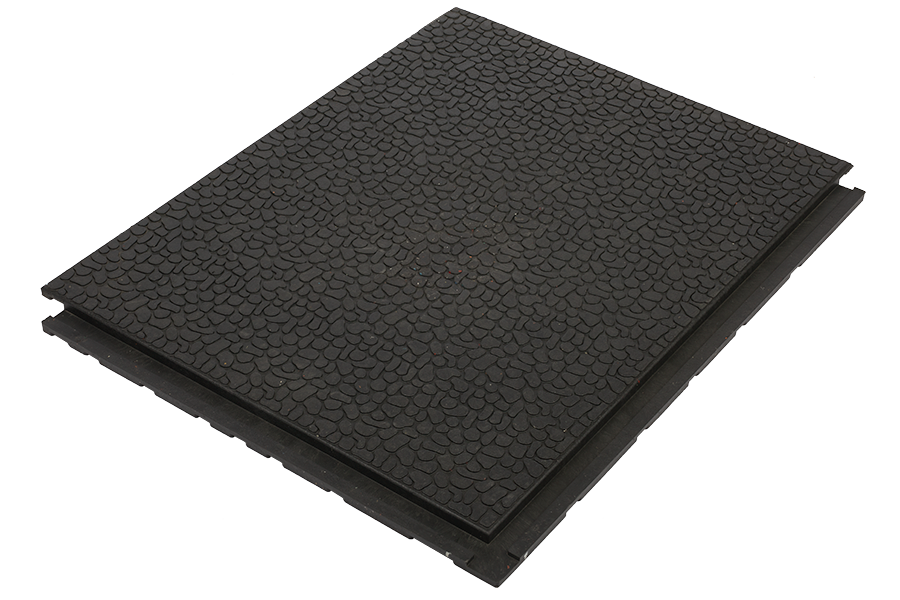

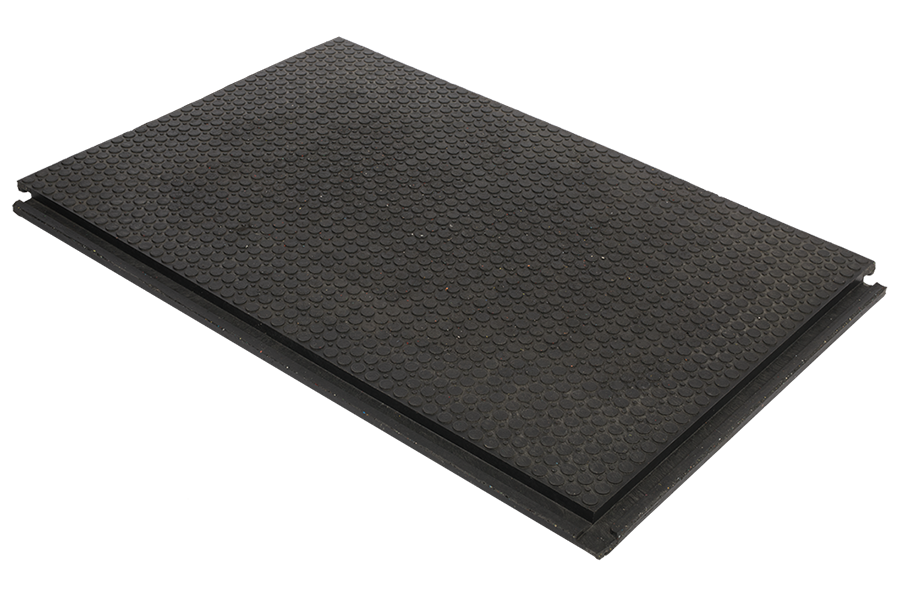

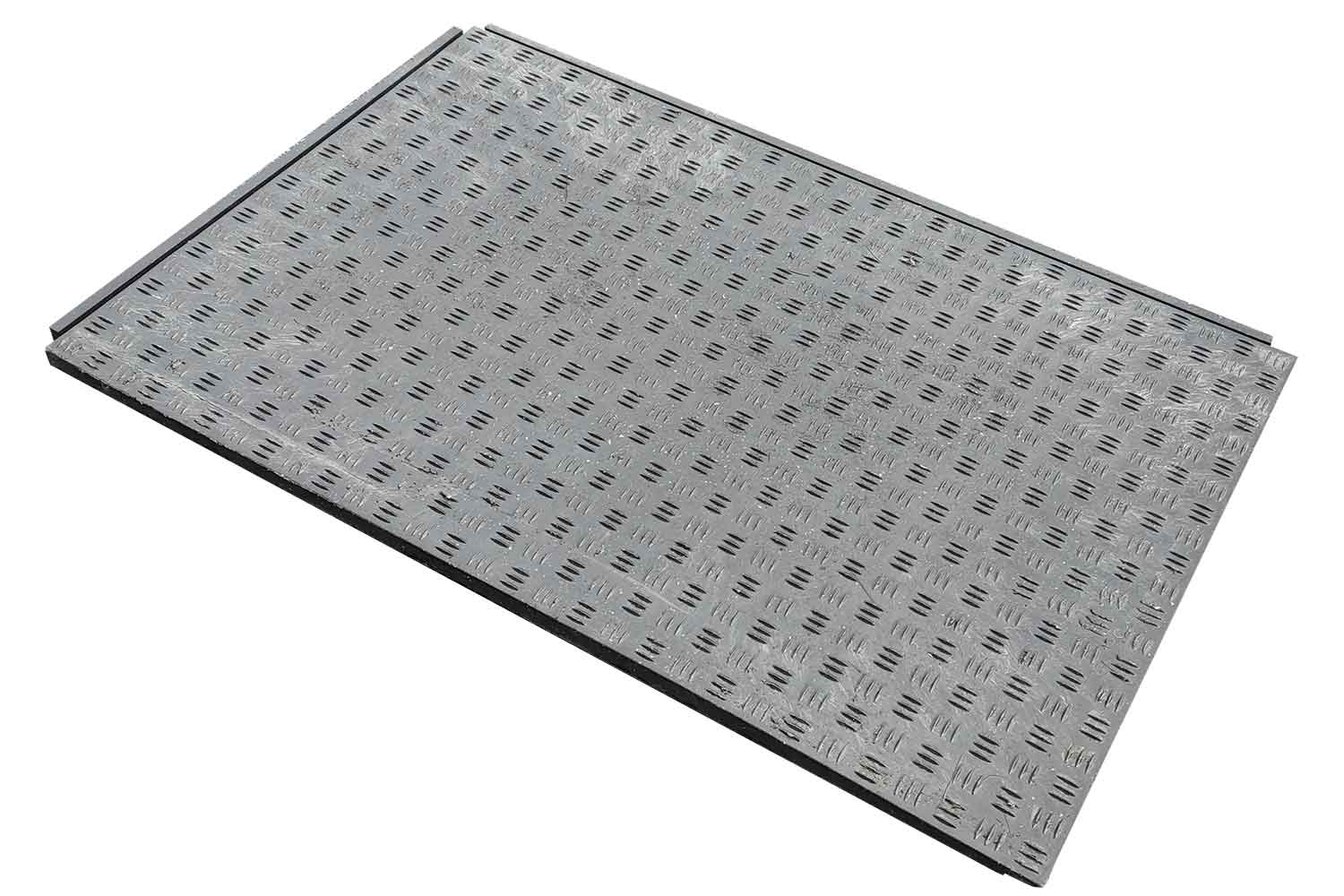

Interlocking on all sides

Designed for stable reinforcement without slipping. The integrated wheel guide keeps the CC container in the track and facilitates work.

No substructure

Thanks to the breakage-resistant and long-lived material, no compacted substructure is required in order to create functional and employee-friendly surfaces.

Easy to handle at up to 18 kg

The low weight allows the CC Trolley Tracks to easily be laid by hand. This makes the plates predestined for stationary and mobile applications.

Quick realisation

Record-breaking installation times and simplified ground preparation significantly reduce construction time. Keep your business running without long interruptions.

Quiet

Rubber-like properties reduce running and rolling noises. Create a quiet environment for customers and employees.

Slip-resistant

The rubber-like recycled PVC material and a nubby texture on the walking area provide a slip-resistant surface. Walkways for a safe working environment on your premises.

Technical data

at a glance

CC Trolley Tracks

18 kg

Weight

1,20 m

Length

Length

51 cm / 54,5 cm

Usable width / outer width

Usable width / outer width

25 mm

Ground depth

Ground depth

25 mm

Height of wheel guides

Height of wheel guides

100 %

Recycled plastic

(post-consumer PVC)

Recycled plastic

(post-consumer PVC)

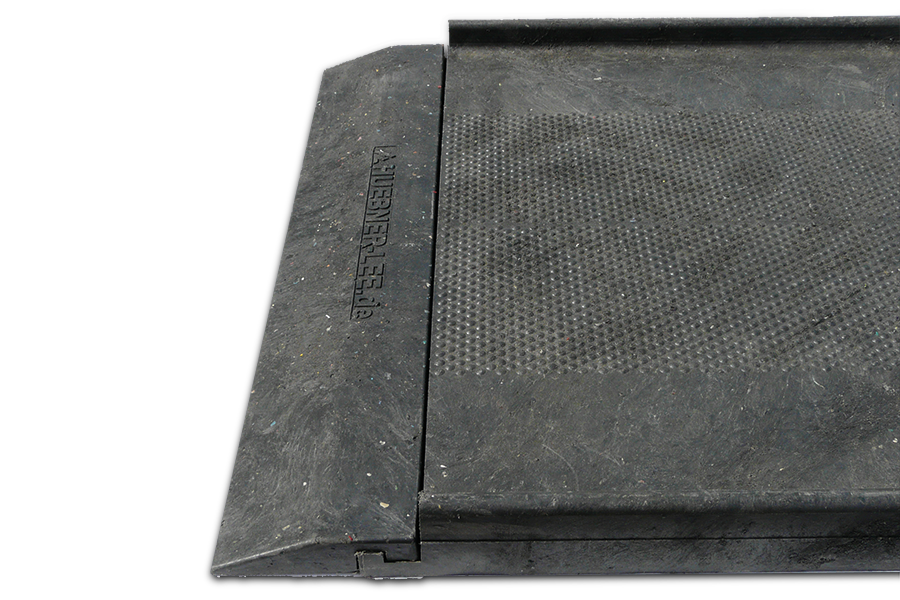

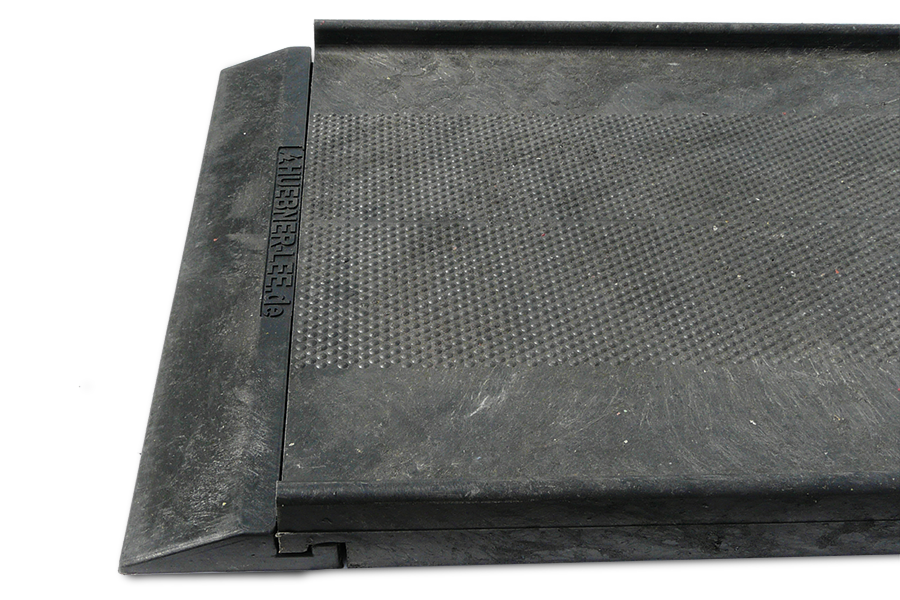

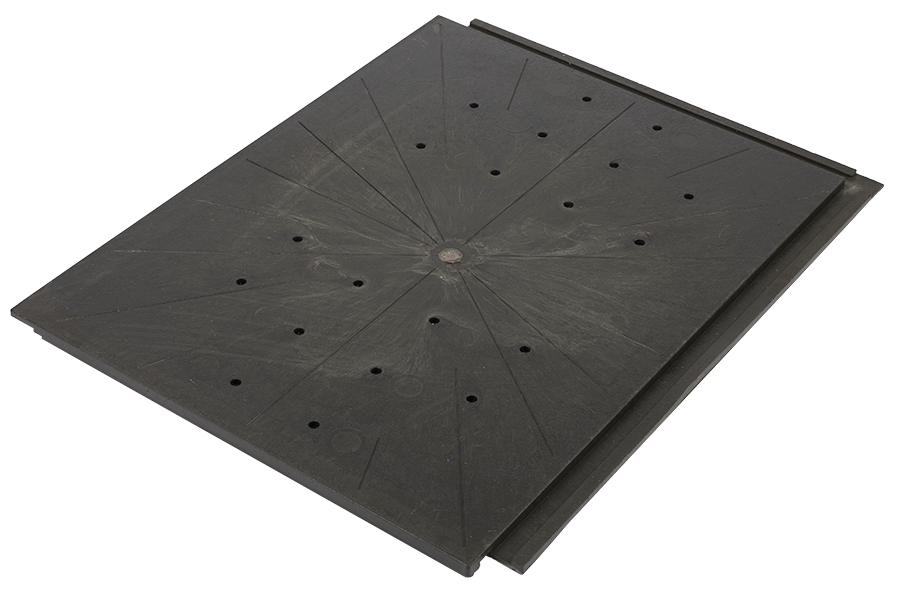

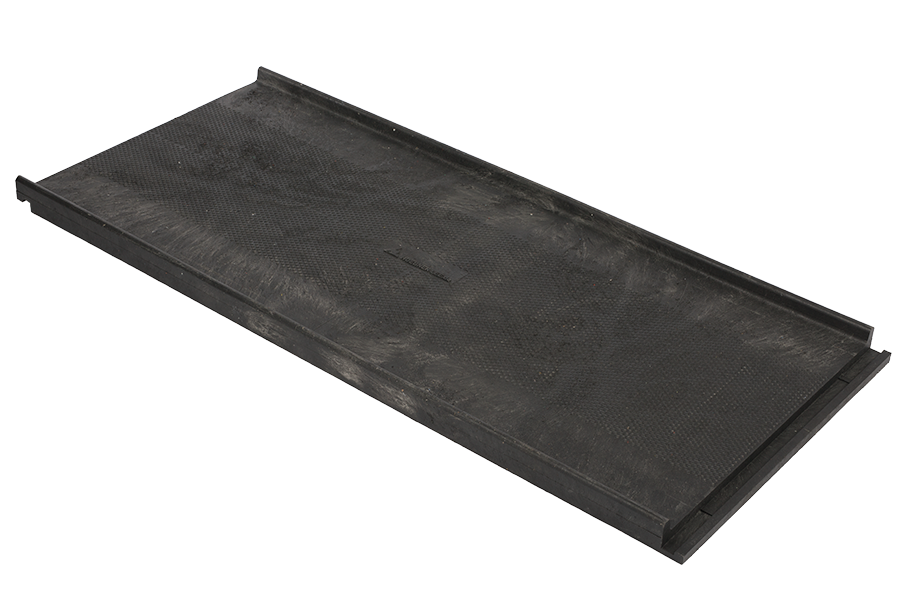

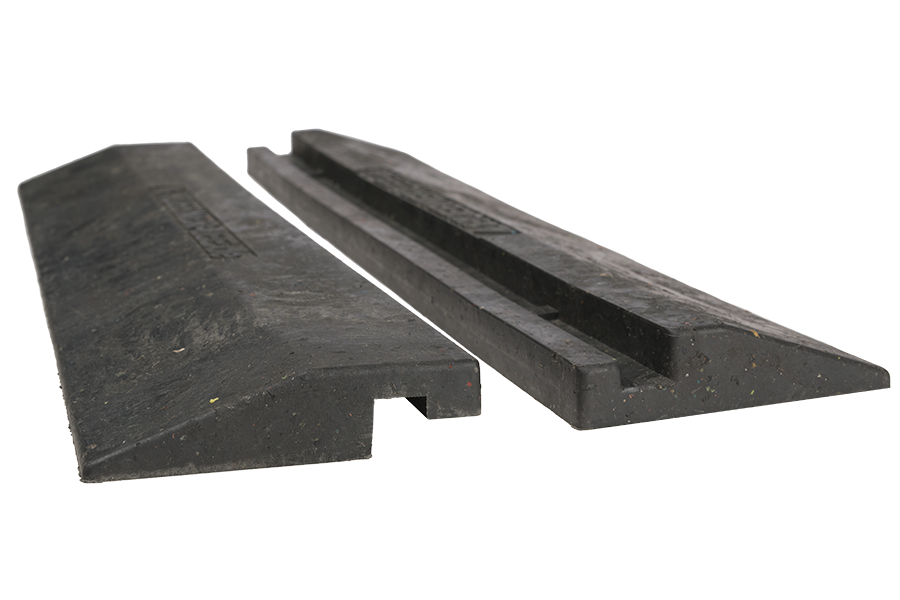

Ramps for CC Trolley Tracks

1,35 kg

Weight

Weight

54,5 cm

Length

Length

11 cm

Width

Width

25 mm

Plate thickness

Plate thickness

Top/bottom

Versions

Versions

100 %

Recycled plastic

(post-consumer PVC)

Recycled plastic

(post-consumer PVC)

Laying instructions

for mobile and stationary installation

Mobile:

- Level surface if necessary

- Lay ribbon fabric

- Observe integrated expansion joint of 5 mm

In cold conditions: lay with ~ 5 mm spacing

In warm conditions: lay with ~ 2 mm spacing

Stationary on non-reinforced surface:

- Min. 3 to 5 cm fine gravel (2 – 5 mm) as levelling and stabilisation layer

- Level surface

- Lay ribbon fabric

- Observe integrated expansion joint of 5 mm

In cold conditions: lay with ~ 5 mm spacing

In warm conditions: lay with ~ 2 mm spacing

In cold conditions: lay with ~ 5 mm spacing

In warm conditions: lay with ~ 2 mm spacing