Multikett

For customer paths and transport routes

Manufactured entirely from recycled post-consumer cable sheathing

Easily reinforce surfaces –

Protect the environment

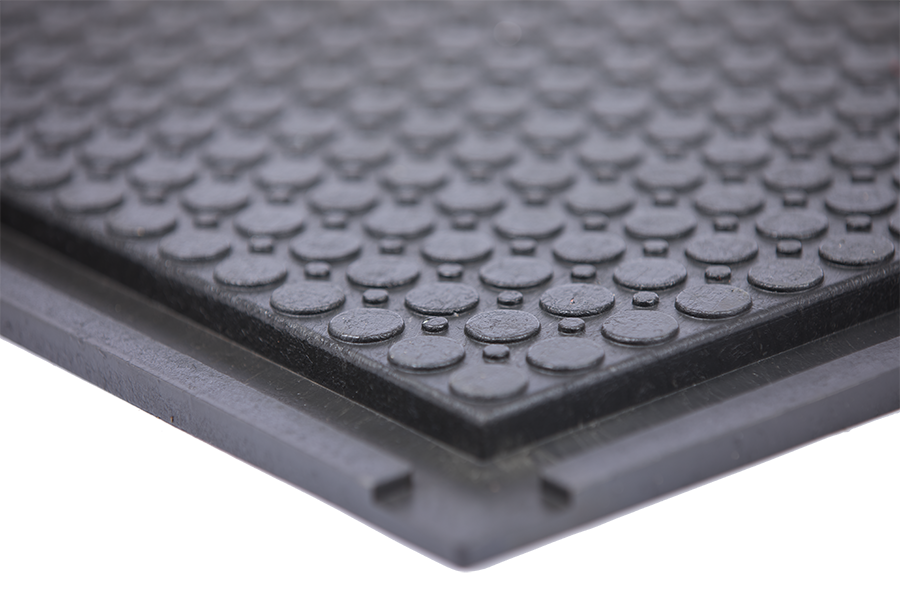

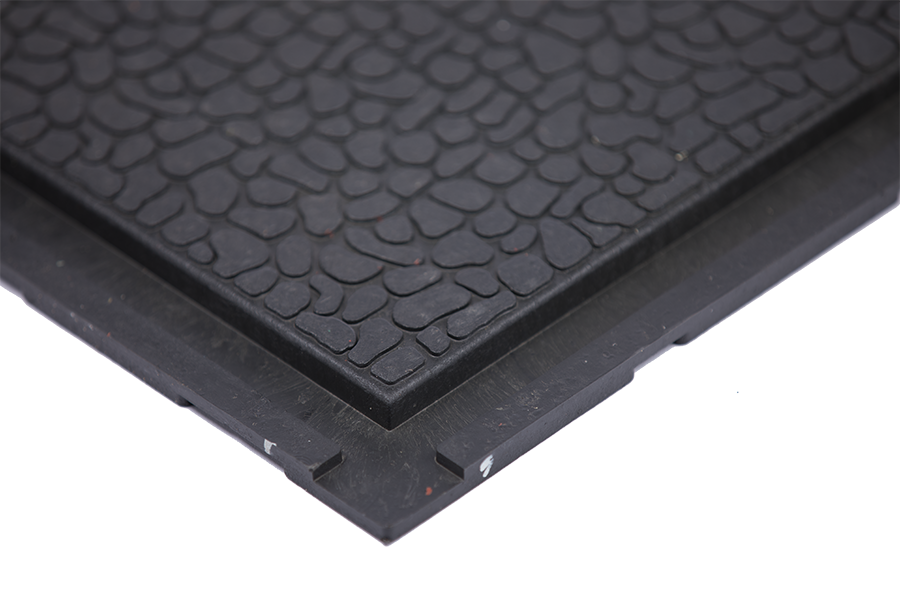

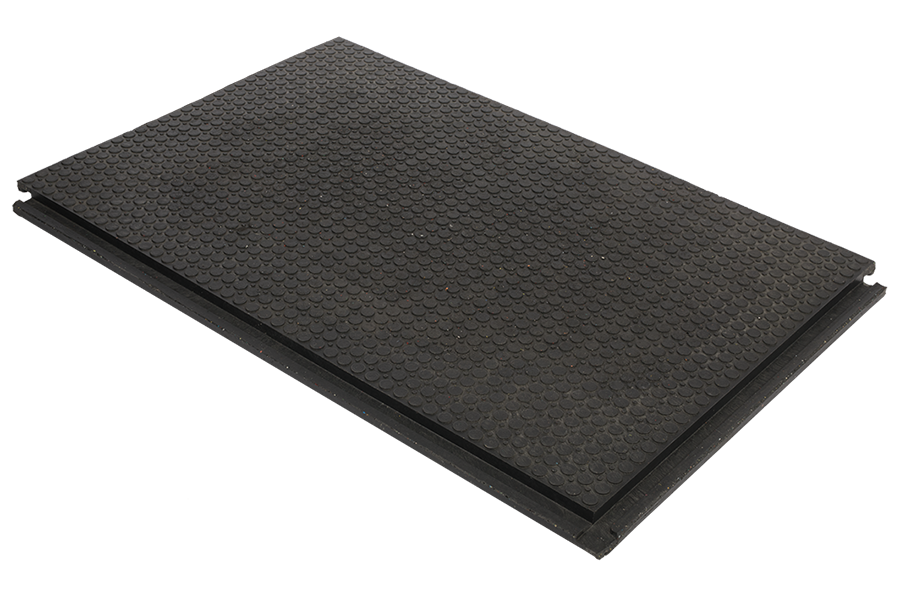

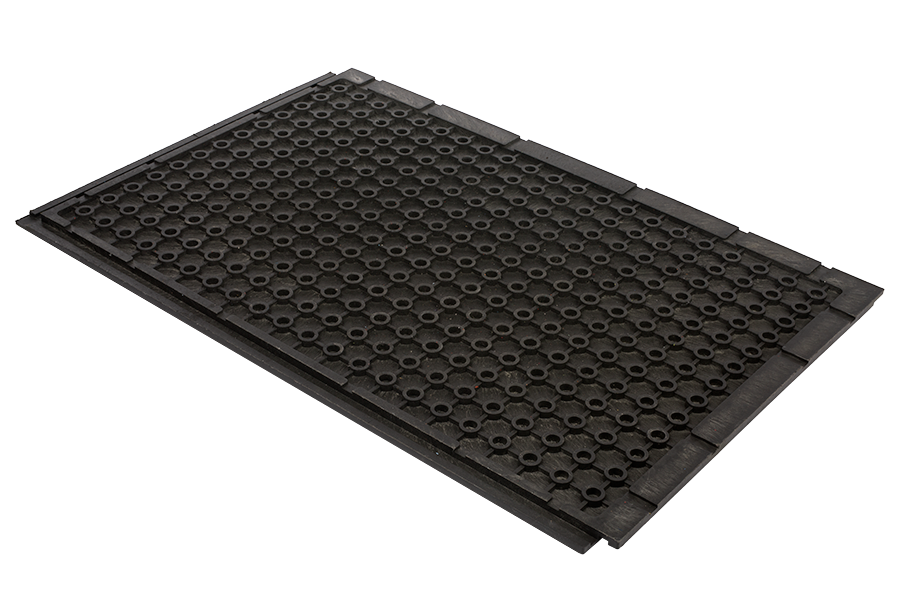

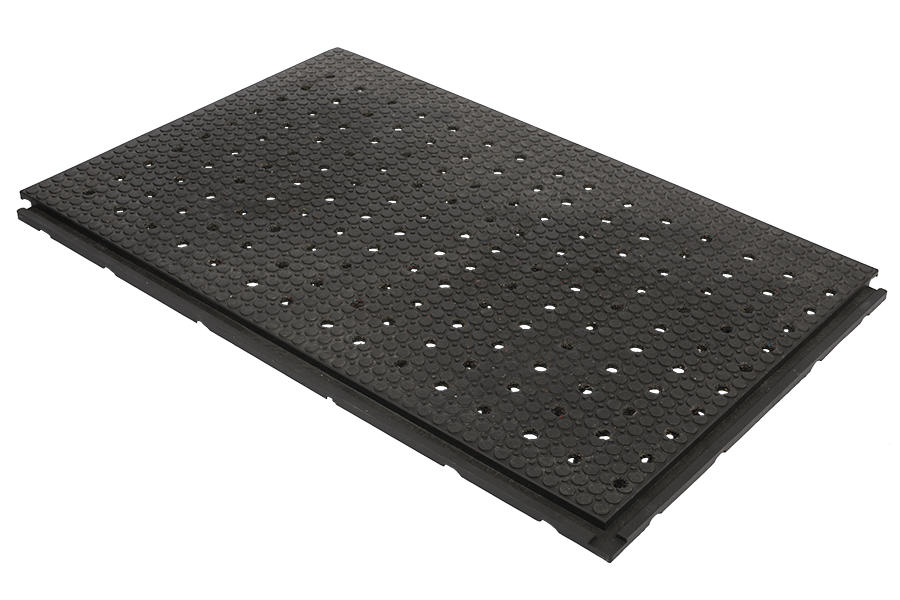

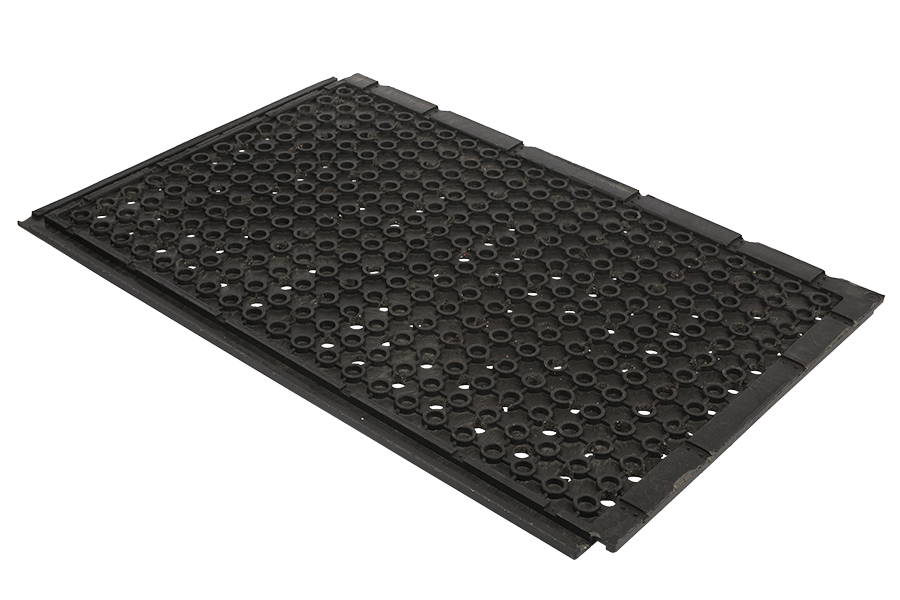

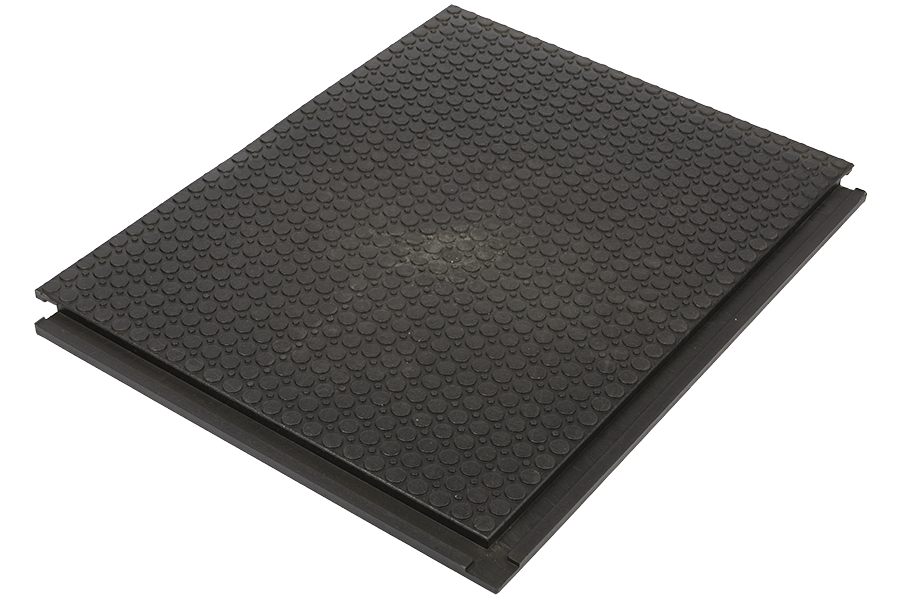

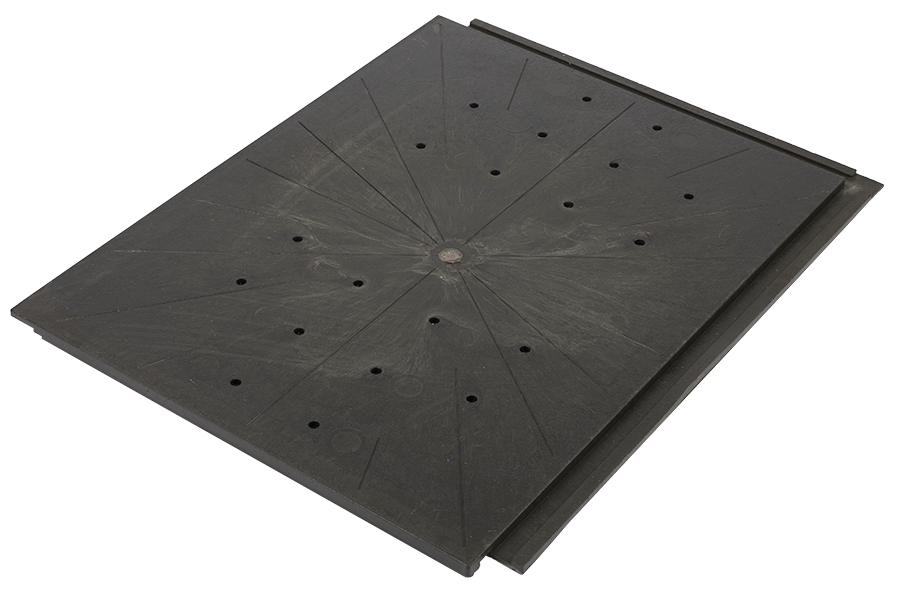

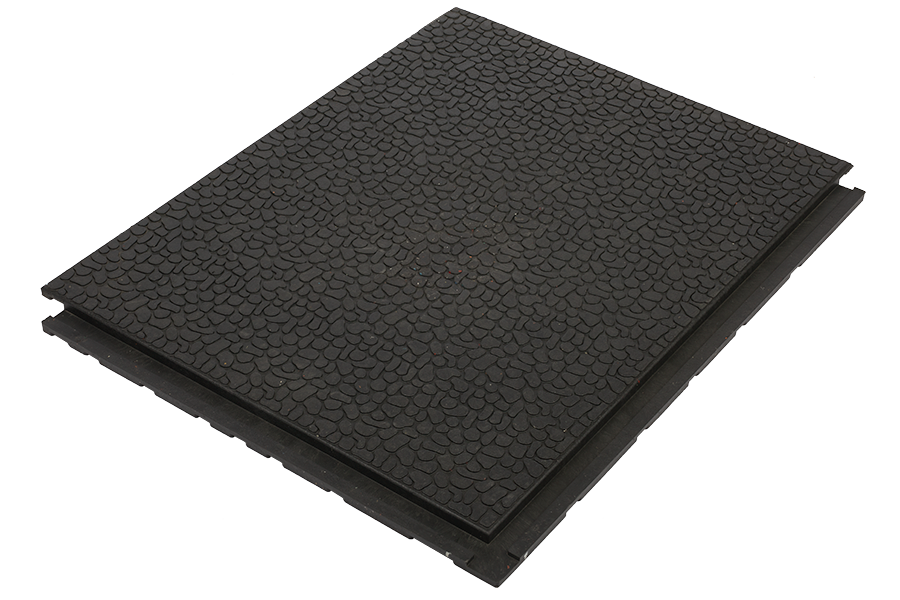

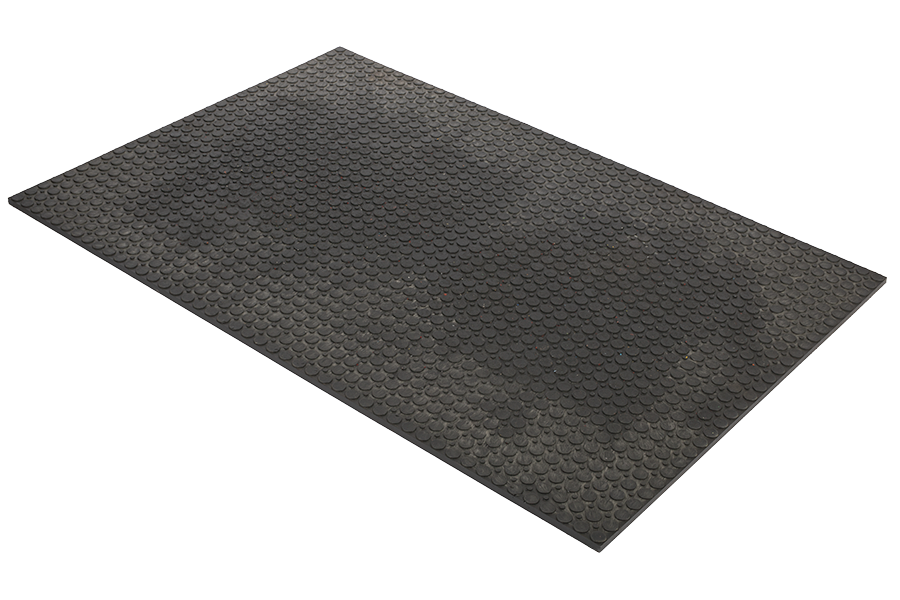

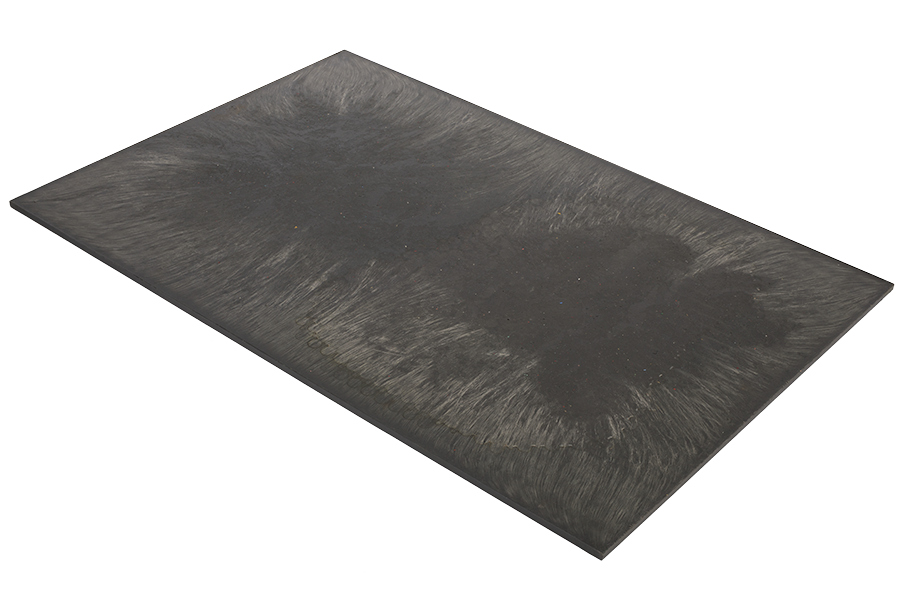

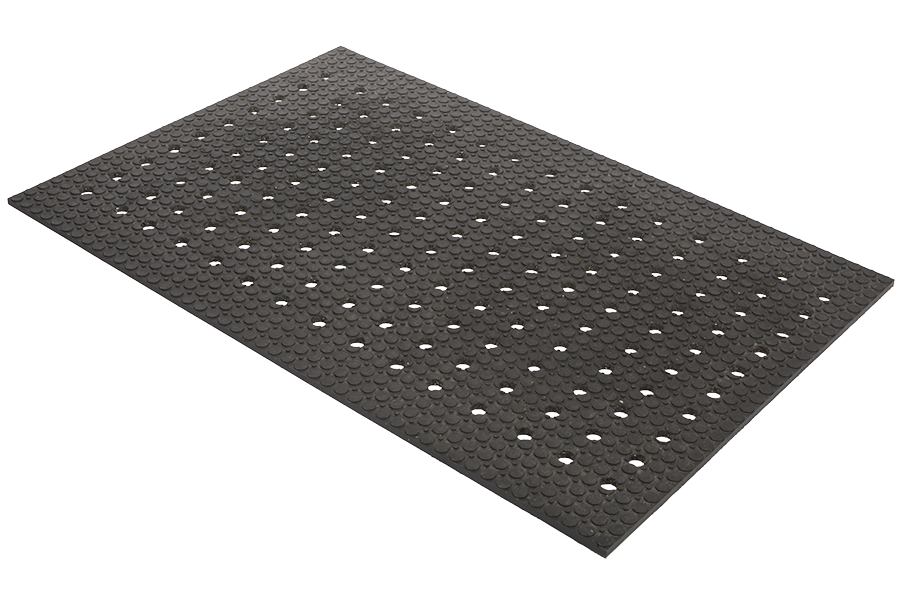

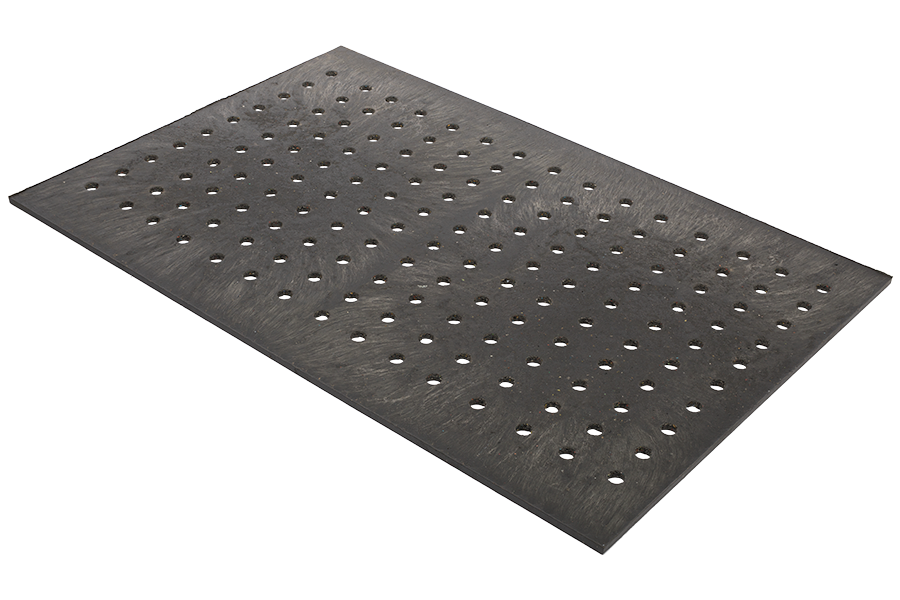

Unpaved surfaces are an obstacle for customers and employees. Our Multikett plates made of non-slip recycled plastic are ideal for transforming unpaved surfaces into customer-friendly areas and logistics routes in no time at all. The ground mats are available in various designs: closed, with openings and in different thicknesses and sizes.

The recycling of waste plastics is not something that can be taken for granted. Vast amounts of our waste still end up in incinerators. The raw material for our plastic mats is obtained from used PVC cable sheathing (origin: EU).

Old becomes new – a cycle for a better future.

The recycling of waste plastics is not something that can be taken for granted. Vast amounts of our waste still end up in incinerators. The raw material for our plastic mats is obtained from used PVC cable sheathing (origin: EU).

Old becomes new – a cycle for a better future.

Alternative to concrete slabs

with impressive advantages

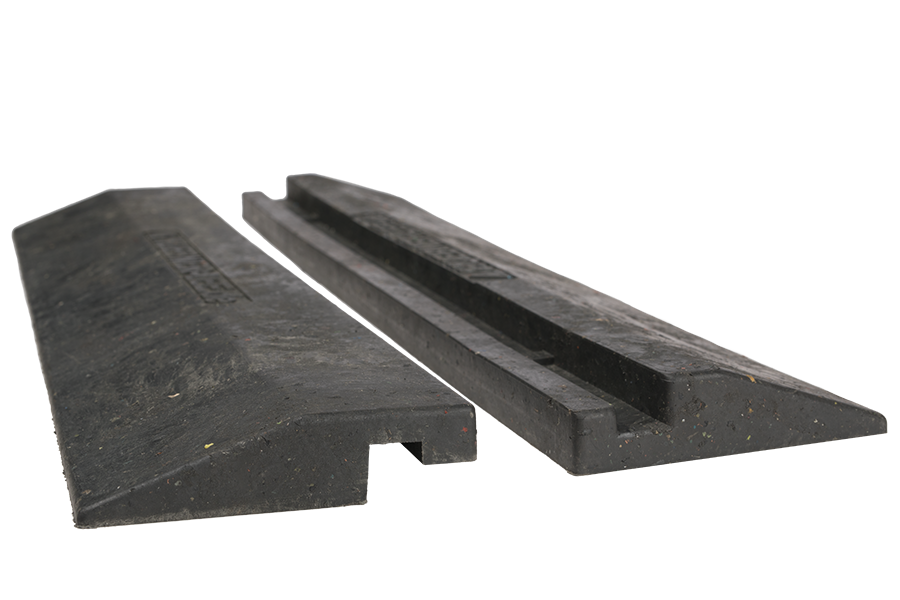

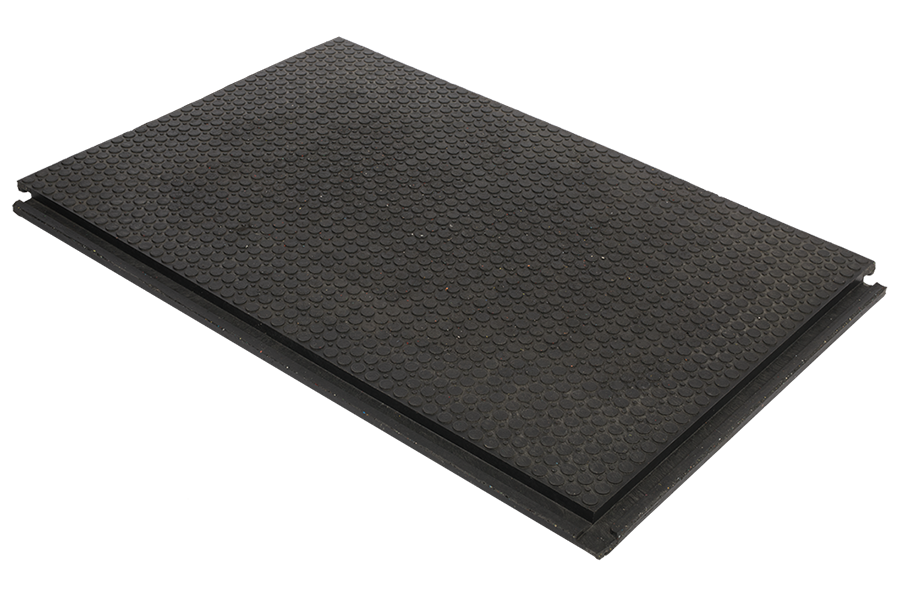

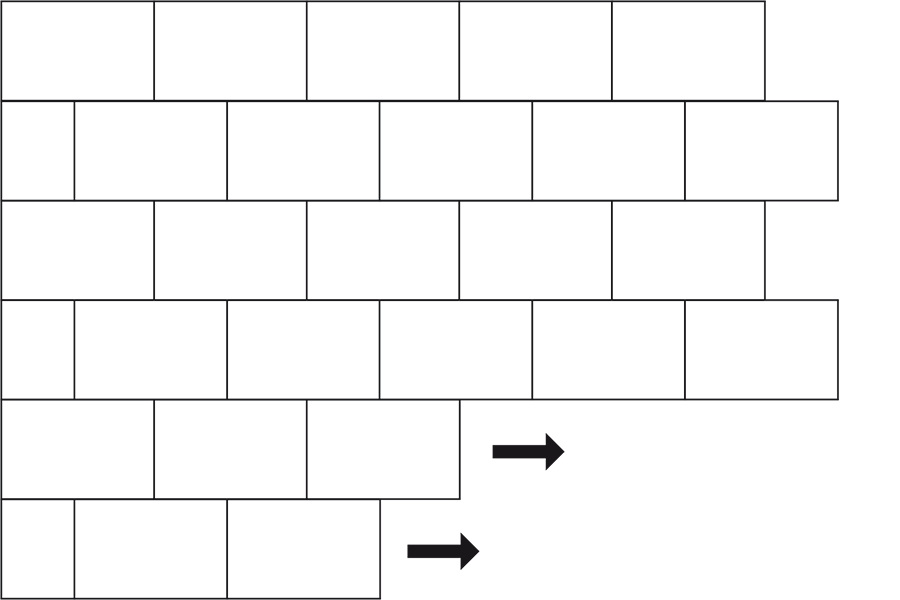

Interlocking on all sides

Fold-and-groove joints on all sides provide stability and transfer loads for stable and level surface area reinforcement.

No substructure

Thanks to the breakage-resistant and long-lived material, no compacted substructure is required in order to create functional and employee-friendly surfaces.

Easy to handle at up to 20 kg

The low weight allows the ground mats to easily be laid by hand. This makes the plates predestined for stationary and mobile applications.

Quick realisation

Record-breaking installation times and simplified ground preparation significantly reduce construction time. Keep your business running without long interruptions.

Quiet

Rubber-like properties reduce running and rolling noises. Create a quiet environment for customers and employees.

Slip-resistant

Recycled PVC material and textured surface provide a slip-resistant surface for both employees and customers to walk on safely.

Technical details at a glance

Benefit now from our sustainable products for practical surface reinforcement and help ensure waste plastics are recycled instead of incinerated.

Brochure (3.4 MB)

Brochure (3.4 MB)

Laying instructions

Mobile:

- Level surface if necessary

- Lay ribbon fabric

- Observe integrated expansion joint of 5 mm

In cold conditions: lay with ~ 5 mm spacing

In warm conditions: lay with ~ 2 mm spacing

Stationary on non-reinforced surface:

- Min. 3 to 5 cm fine gravel (2 – 5 mm) as levelling and stabilisation layer

- Level surface

- Lay ribbon fabric

- Observe integrated expansion joint of 5 mm

In cold conditions: lay with ~ 5 mm spacing

In warm conditions: lay with ~ 2 mm spacing

Note:

- Lay with offset > T-joint

- Easy to cut to size using a circular saw (carbide blade)

- Pay attention to expansion joints