Species-appropriate outdoor cattle enclosures

Ecological, without substructure & flexible

Heavily frequented enclosure or watering areas quickly develop into unhygienic and steadily deepening mud holes as a result of the point loads from cattle hooves. Concrete – the cheapest option for paving – is dry, but the surface becomes soil-sealed and irreparably ruined. Furthermore, such hard surfaces are bad for the animals’ joints.

How can we provide cattle with animal-friendly and ecologically sustainable surface reinforcement?

The goal is to create level, dry and clean paths and watering stations that are easy on the joints.

HÜBNER-LEE’s solution to this is the TTE® system.

How can we provide cattle with animal-friendly and ecologically sustainable surface reinforcement?

The goal is to create level, dry and clean paths and watering stations that are easy on the joints.

HÜBNER-LEE’s solution to this is the TTE® system.

TTE® stands for Total, Traffic Exopave

- Does WITHOUT a substructure thanks to the high self-supporting capacity of the elements

- Laid directly on the ground (ON-TOP principle, no excavation necessary)

- Separation layer and base course in a single system

- Can be laid QUICKLY and EASILY by the customer

- For cattle halls/corrals and paths

- Ensures drainage thanks to ON-TOP construction principle and high joint ratio (for cattle halls, TTE® is filled with concrete)

- Remains permanently level thanks to 4-sided connection system

- Durable and retains its value, can be removed and reused without damage

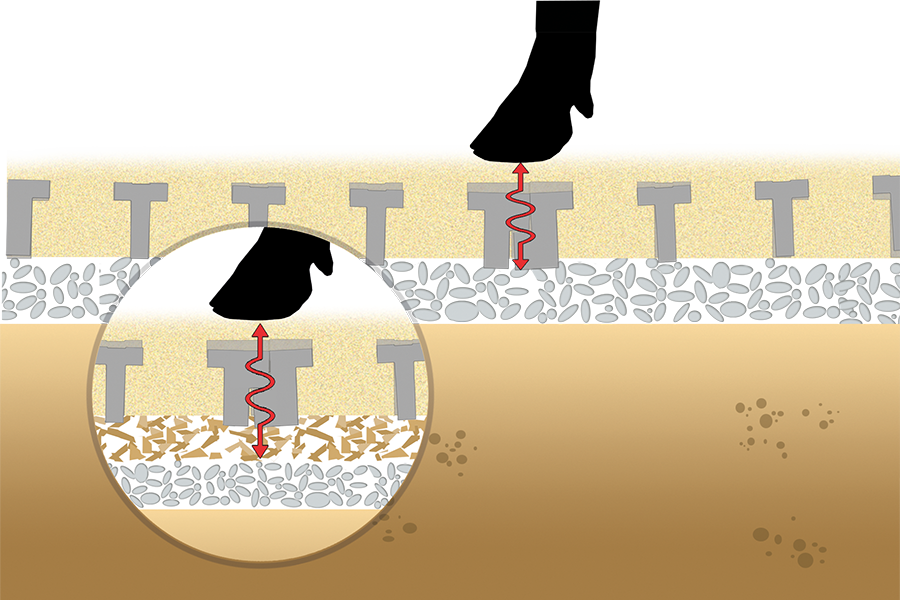

- Shock-absorbing => easy on the joints thanks to the flexible connection between individual elements

WHAT is TTE®?

Separation layer & base course in a single system

TTE® elements are significantly more stable and heavier than other riding arena grids, paddock mats or turf honeycombs. Thanks to its high self-supporting capacity and intelligent load distribution, no base course material is required at all, and the TTE® construction principle can be used to lay the reinforcement directly on the surface.

TTE® Total Traffic Exopave

- TTE® replaces the base course. All you require is a 0-5 cm levelling layer, the chamber filling and a covering layer if necessary.

- Hence, with TTE®, you save significantly on costs for materials and labour.

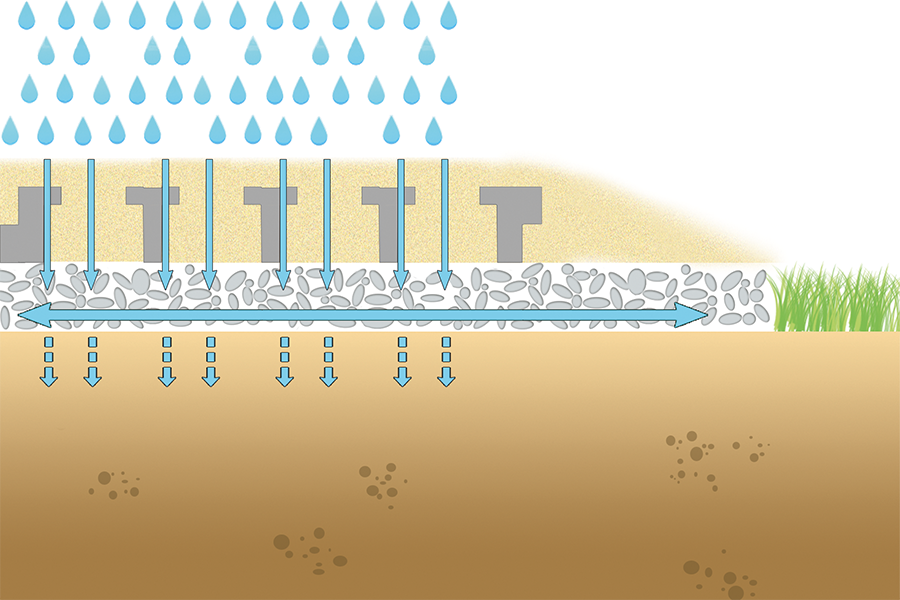

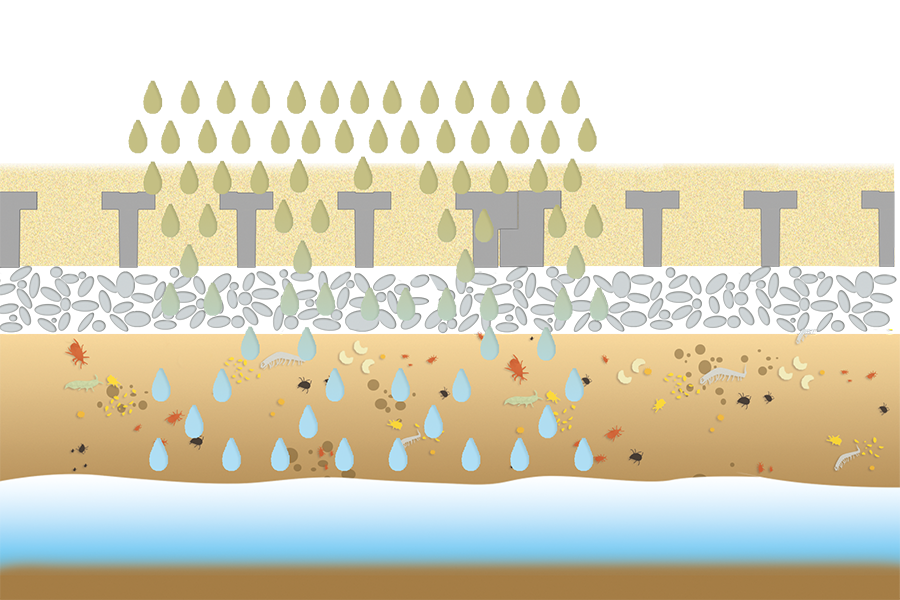

- Thanks to the ON-TOP principle, water can continuously seep into the ground, and the area can be used all year round.

HOW does TTE® work? (With cattle paths as an example.)

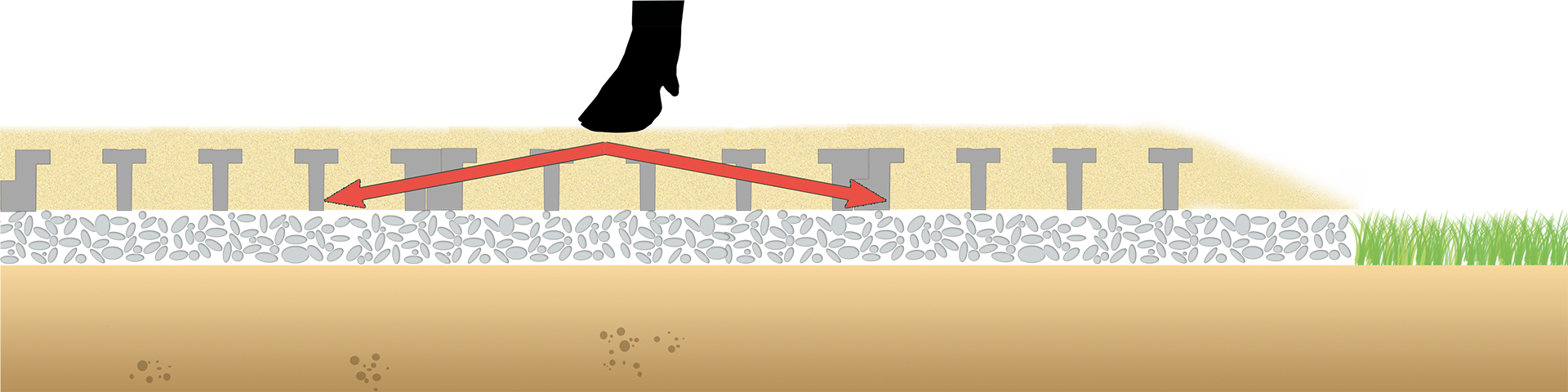

Build WITHOUT A SUBSTRUCTURE thanks to intelligent load distribution.

Thanks to the high self-supporting capacity and 4-sided connection principle of the TTE® elements, point loads from hooves are distributed over a wide area. Hence, TTE® replaces the base course. The ground of the riding arena or the ground covering in the enclosure is neither soil-sealed nor compacted. This eliminates the need for cost-intensive materials and construction labour (excavation, procurement and installation of base course material).

WHICH functions does the TTE® system offer?

(With cattle paths as an example.)

NO more MUD

- No soil sealing/compaction of the ground

- Long-term permeability

- Features forced joints

=> mud formation is impossible

Permanently LEVEL

- 4-sided connection system => permanently level

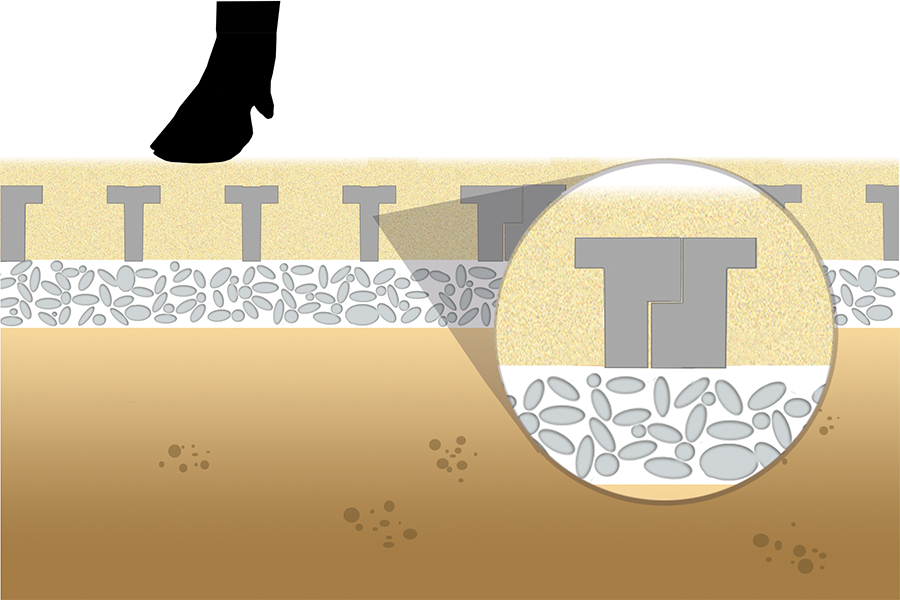

Joint-friendly

- Installed directly on natural ground => hard on soft

- Reduced wear on joints and underlying layer

- Better shock absorption thanks to elastic layer => forest floor effect

Ecological & low-odour

- Preserved topsoil (microorganisms) filters and breaks down pollutants

- Low-odour, hygienic surfaces

- Does not disturb the ground => significantly facilitates approval procedures

The TTE® construction principle stands for species-appropriate animal husbandry and is environmentally sustainable.

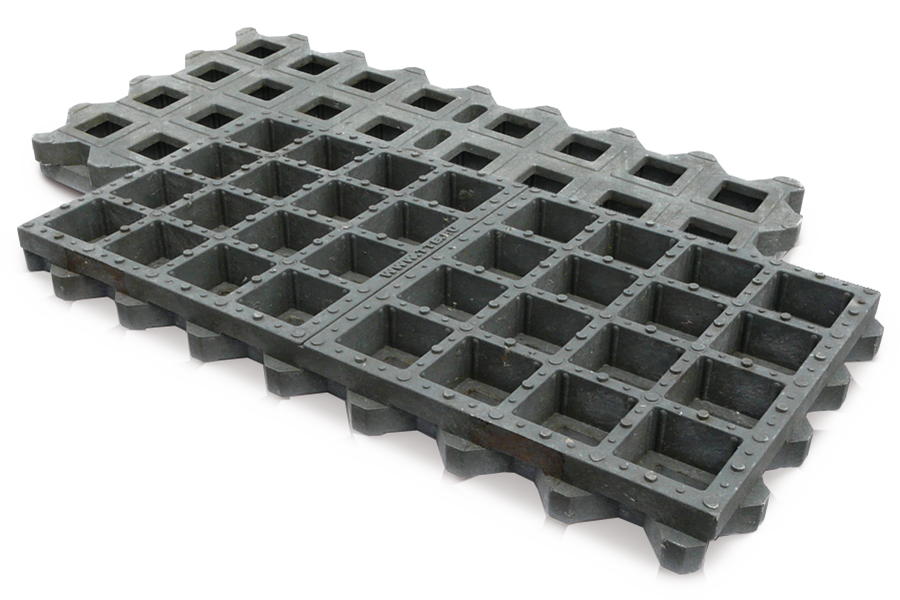

TTE® MultidrainPLUS 2000

| Material | 100 % recycled plastic, environmentally neutral |

| Item no. | 1351.4080 |

| Color | Grey |

| Dimensions | 800 x 400 x 60 mm with 32 chambers (size 80 x 80 mm) |

| Teeth | 1,5 cm, 1m² = 3,125 teeth |

| Chamber percentage | 72 % of total area |

| Wall thickness | Approx. 14 mm top side, approx. 15 mm bottom side |

| Top side | Anti-slip nubbed fins |

| Bottom side | Wide T-support 4.2 cm |

| Weight | approx. 8.7 kg (approx. 27 kg/m²) |

| Load capacity, static | Approx. 147 kN (approx. 15t) per test piece (approx. 20 x 20 cm, consisting of 4 unfilled chambers, certified by TÜV Süd) |

| Incline/slopes | Up to approx. 10 % |

| Per pallet | 28.8m² (90 pieces) |

| Max. delivery quantity per truck | 864 m² (30 pallets) |

| Pallet size | LxWxH 123 x 85 x 200 cm |