TTE® HORSE WALKERELASTIC -

springy, easy on the joints and highly robust

Horses need several hours of exercise every day to stay physically and mentally healthy. Horse walkers are an important tool to enable horses to get this exercise.

Horses are flight animals and intuitively prefer the shortest path and therefore primarily move along the innermost circle in a horse walker. The extremely high frequency of use and the point loads of the horse’s hooves result in a high degree of wear on the surface, even on paved surfaces with a deep gravel layer.

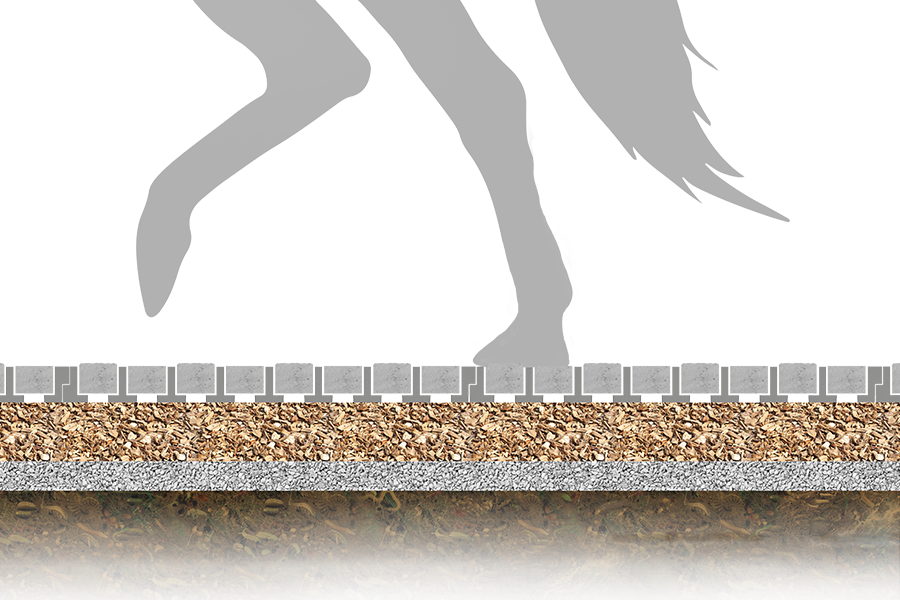

Horse exercisers with the TTE® HORSE WALKERELASTIC construction are different. The resilient elastic wood layer acts like a shock absorber and buffers the high loads.

Horses are flight animals and intuitively prefer the shortest path and therefore primarily move along the innermost circle in a horse walker. The extremely high frequency of use and the point loads of the horse’s hooves result in a high degree of wear on the surface, even on paved surfaces with a deep gravel layer.

Horse exercisers with the TTE® HORSE WALKERELASTIC construction are different. The resilient elastic wood layer acts like a shock absorber and buffers the high loads.

TTE® HORSE WALKER ELASTIC: resilient like a shock absorber

TTE® MultidrainPLUS

The robust paddock grid

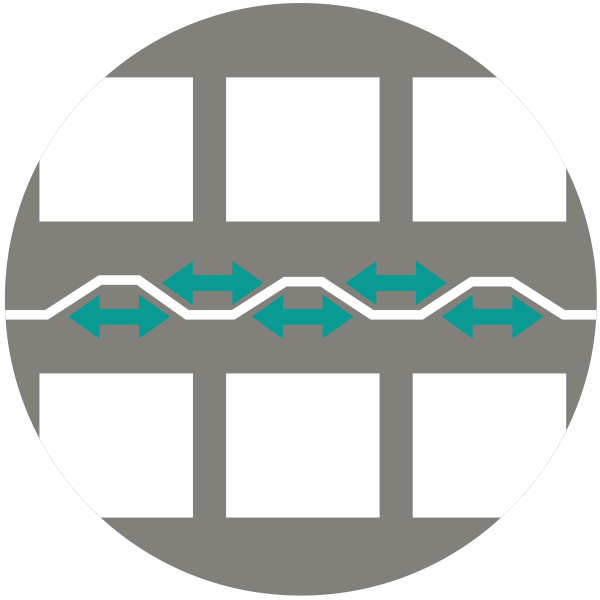

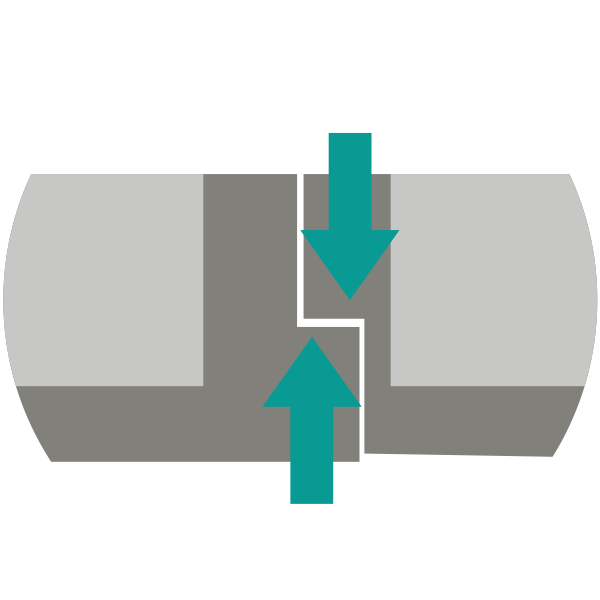

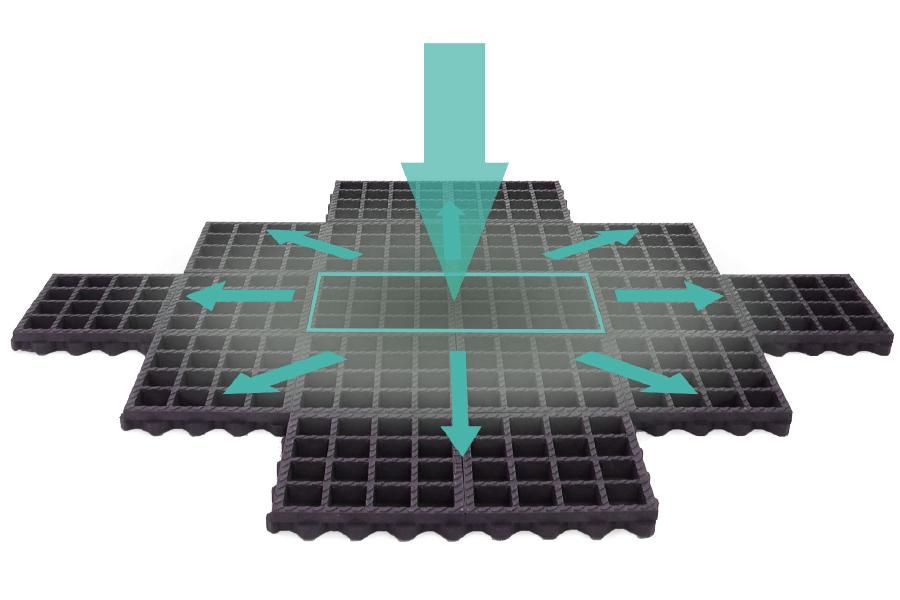

The TTE® paddock panels are connected horizontally and vertically with the aid of solid pins. It is not possible to break off individual paddock plates. In addition, the 2:1 format and a total weight of 27 kg/m², in combination with the intelligent bond, create an extremely load-bearing snowshoe effect.

This enables load distribution over a wide area, allowing horse walkers, paddocks, riding arenas and exercise areas to be built easily and made level without a substructure.

This enables load distribution over a wide area, allowing horse walkers, paddocks, riding arenas and exercise areas to be built easily and made level without a substructure.

Top and bottom view of TTE®

80 x 40 x 6 cm

Dimensions

27 kg per square metre

8.7 kg per plate

Weight

8.7 kg per plate

Weight

inner: 15 mm

outer: 20 mm

Fin width

outer: 20 mm

Fin width

In hormony with nature -

Horse walker construction without substructure

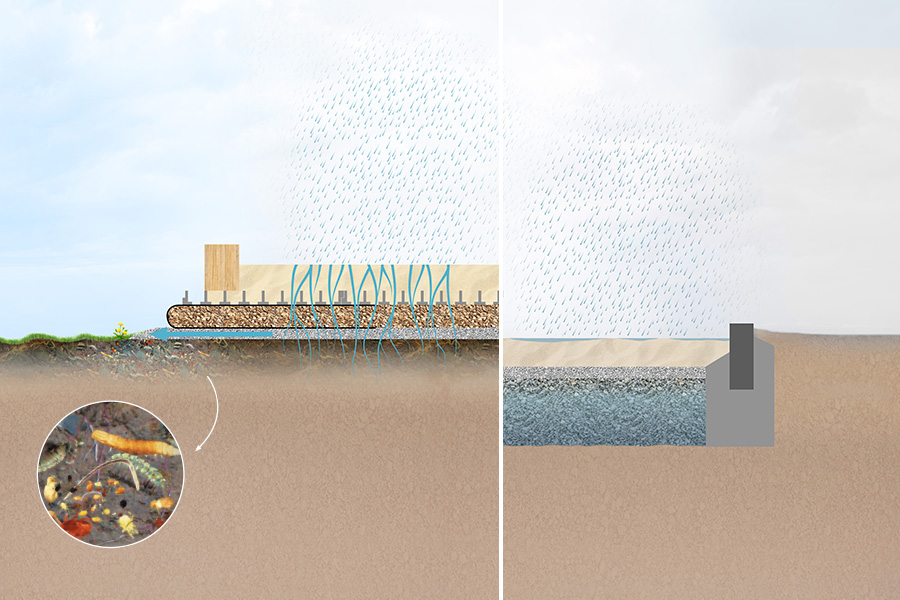

Conventional horse walker construction relies on a gravel base layer of up to 60 cm in height for a load-bearing structure in order to be able to permanently absorb the point loads of the horses' hooves.

The TTE® construction principle is different: The horizontal load distribution of the solid TTE® grids works according to the principle of a snowshoe: point loads are distributed areally through the composite of the panels, which significantly reduces the demands on the substructure.

The TTE® construction principle is different: The horizontal load distribution of the solid TTE® grids works according to the principle of a snowshoe: point loads are distributed areally through the composite of the panels, which significantly reduces the demands on the substructure.

Left: On-top construction with TTE®, right: conventional construction method

The advantages of the on-top construction

- No bathtub effect - lateral drainage even in the event of heavy rainfall

- Lower costs due to material savings, shorter construction time and elimination of disposal costs

- Self-construction possible

- Preservation of natural soil life

- Construction possible in almost all soil conditions

- Simpler approval, as there is hardly any input of foreign material

Two solutions

for individual requirements

We offer two options for the construction of your horse exerciser.

What they both have in common: the springy elastic wood layer, which acts like a shock absorber and makes the horse exerciser much more resistant to the high loads.

What they both have in common: the springy elastic wood layer, which acts like a shock absorber and makes the horse exerciser much more resistant to the high loads.

TTE® HORSE WALKERELASTIC

option 1

With the TTE® HORSE WALKERELASTIC construction method, the TTE® gridS are filled with the TTE® PaverGRIP and covered with a rubber mat.

Joint protection

- Optimal shock absorption and energy recovery due to resilient elastic wood layer

- Protection of the horse‘s joints, without overloading tendons and ligaments

- Heat generation by macro- and microorganisms in wood and topsoil

- Insulating effect of the wood chips

- Faster thawing of ice and snow

- No excavation of the living soil zone

- Preservation of important functions such as e.g. degradation of nitrate and ammonia

- Powerful, vertical surface drainage

- + Lateral drainage due to on-top construction

- Year-round usability

- Dauerhafte Ebenheit durch robuste Verzahnung

- Kein Aufstellen einzelner Platten möglich

- Load distribution over a wide area due to horizontal and vertical bonding

- Elimination of the substructure

- Reduction of effort and costs

- No soil compaction

TTE® HORSE WALKERELASTIC

option 2

In the TTE® HORSE WLAKERELASTIC construction method, the TTE® grids are filled alternately with TTE® PaverGRIP and normal TTE® Pavers for hgih slip resistance

Joint protection

- Optimal shock absorption and energy recovery due to resilient elastic wood layer

- Protection of the horse‘s joints, without overloading tendons and ligaments

- Heat generation by macro- and microorganisms in wood and topsoil

- Insulating effect of the wood chips

- Faster thawing of ice and snow

- No excavation of the living soil zone

- Preservation of important functions such as e.g. degradation of nitrate and ammonia

- Powerful, vertical surface drainage

- + Lateral drainage due to on-top construction

- Year-round usability

- Dauerhafte Ebenheit durch robuste Verzahnung

- Kein Aufstellen einzelner Platten möglich

- Load distribution over a wide area due to horizontal and vertical bonding

- Elimination of the substructure

- Reduction of effort and costs

- No soil compaction

Simple replacement of individual components, such as rubber mat or pavers, instead of costly renovation of the entire system.

No worries about the wood!

The wood chips of the elastic wood layer rot over the years - but at a much slower rate due to the stored moisture and the exclusion of oxygen. The raw fibre remains intact and continues to guarantee the high evenness, shock absorption and water permeability. The elastic wood layer does not need to be replaced.

Over 20 years of satisfied customers confirm this natural construction method.

The wood chips of the elastic wood layer rot over the years - but at a much slower rate due to the stored moisture and the exclusion of oxygen. The raw fibre remains intact and continues to guarantee the high evenness, shock absorption and water permeability. The elastic wood layer does not need to be replaced.

Over 20 years of satisfied customers confirm this natural construction method.