TTE® RIDING ARENA -

Riding arenas with maximum performance

Particularly important when building riding arenas for dressage and show jumping: maximum performance and healthy, safe riding conditions. And that, if possible, at any time of the year and in any weather.

With the TTE® RIDING ARENA and TTE® RIDING ARENAELASTIC construction principle, you create riding arenas with shock-absorbing and constant riding properties and thus ideal training conditions for horse and rider.

At the same time, both construction methods are sustainable and ecological and protect the climate, soil life and nature.

With the TTE® RIDING ARENA and TTE® RIDING ARENAELASTIC construction principle, you create riding arenas with shock-absorbing and constant riding properties and thus ideal training conditions for horse and rider.

At the same time, both construction methods are sustainable and ecological and protect the climate, soil life and nature.

TTE® RIDING ARENA: ideal riding characteristics for dressage and show jumping.

TTE® MultidrainPLUS

The robust paddock grid

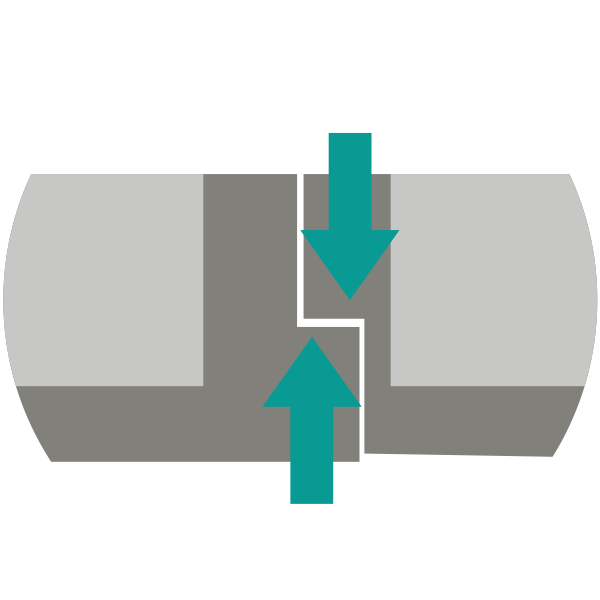

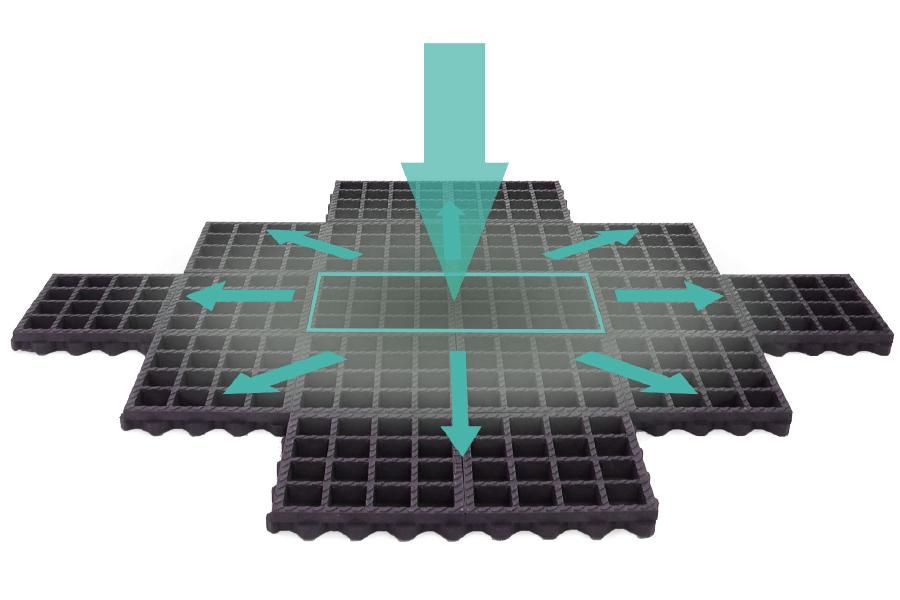

The TTE® paddock panels are connected horizontally and vertically with the aid of solid pins. It is not possible to break off individual paddock plates. In addition, the 2:1 format and a total weight of 27 kg/m², in combination with the intelligent bond, create an extremely load-bearing snowshoe effect.

This enables load distribution over a wide area, allowing paddocks, riding arenas and exercise areas to be built easily and made level without a substructure.

This enables load distribution over a wide area, allowing paddocks, riding arenas and exercise areas to be built easily and made level without a substructure.

Top and bottom view of TTE®

80 x 40 x 6 cm

Dimensions

27 kg per square metre

8.7 kg per plate

Weight

8.7 kg per plate

Weight

inner: 15 mm

outer: 20 mm

Fin width

outer: 20 mm

Fin width

In hormony with nature -

Riding arena construction without substructure

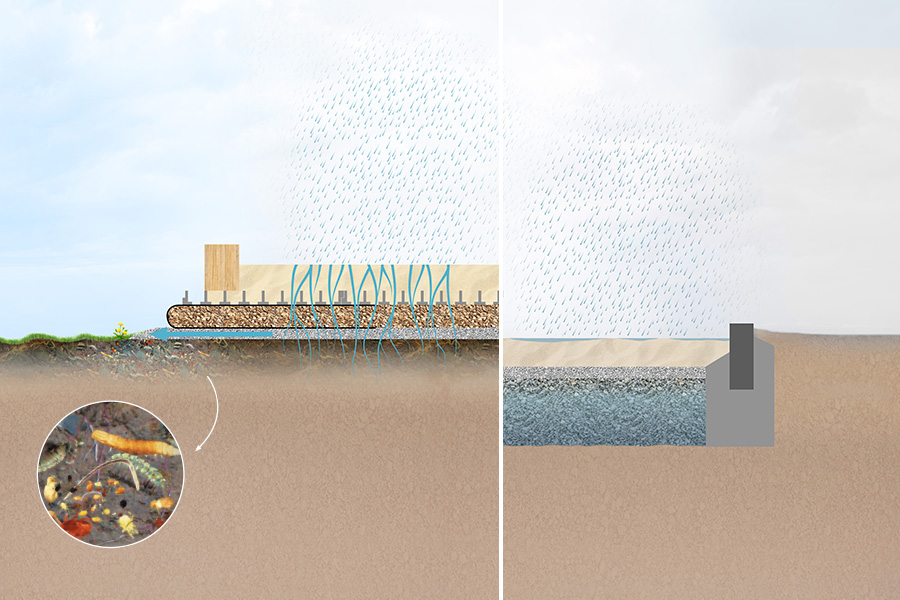

Conventional riding arena construction relies on a gravel base layer of up to 60 cm in height for a load-bearing structure in order to be able to permanently absorb the point loads of the horses' hooves.

The TTE® construction principle is different: The horizontal load distribution of the solid TTE® grids works according to the principle of a snowshoe: point loads are distributed areally through the composite of the panels, which significantly reduces the demands on the substructure.

The TTE® construction principle is different: The horizontal load distribution of the solid TTE® grids works according to the principle of a snowshoe: point loads are distributed areally through the composite of the panels, which significantly reduces the demands on the substructure.

Left: On-top construction with TTE®, right: conventional construction method

The advantages of the on-top construction

- No bathtub effect - lateral drainage even in the event of heavy rainfall

- Lower costs due to material savings, shorter construction time and elimination of disposal costs

- Self-construction possible

- Preservation of natural soil life

- Construction possible in almost all soil conditions

- Simpler approval, as there is hardly any input of foreign material

Two solutions

for individual requirements

We offer two construction methods for riding arena construction without substructure: TTE® RIDING ARENA for simple and quick construction and TTE® RIDING ARENAELASTIC with a resilient elastic wood layer for even more riding comfort.

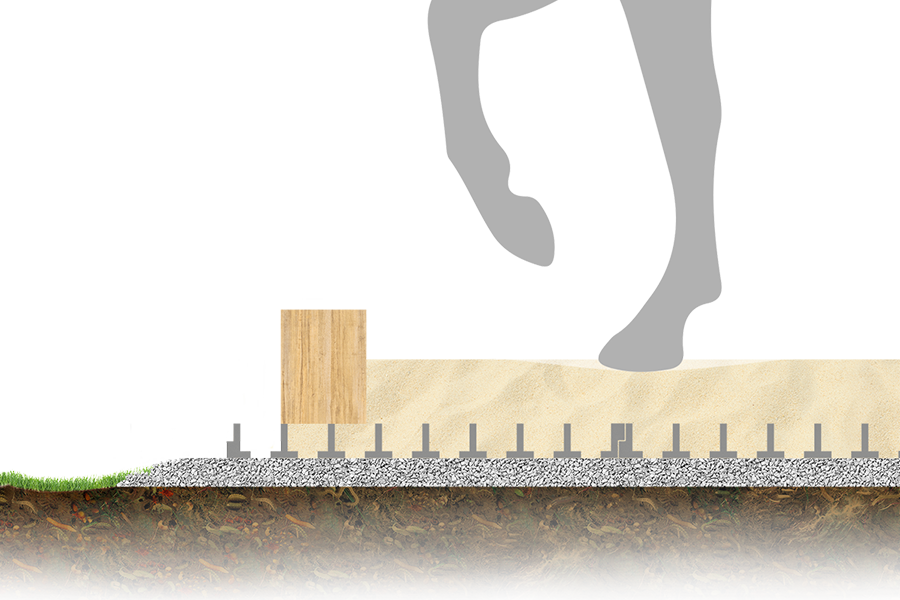

TTE® RIDING ARENA

With the TTE® RIDING ARENA construction method, the TTE® elements are laid directly on a 5 cm high fine gravel levelling layer.

Preservation of soil life

- No excavation of the living soil zone

- Preservation of important functions such as soil loosening

- Efficient, vertical surface drainage + lateral drainage through on-top construction

- Year-round usability

- Durable evenness due to robust interlocking joints

- No setting up of individual panels possible

- Load distribution over a wide area due to horizontal and vertical link

- No need for substructure

- Reduction of effort and costs

- No soil compaction

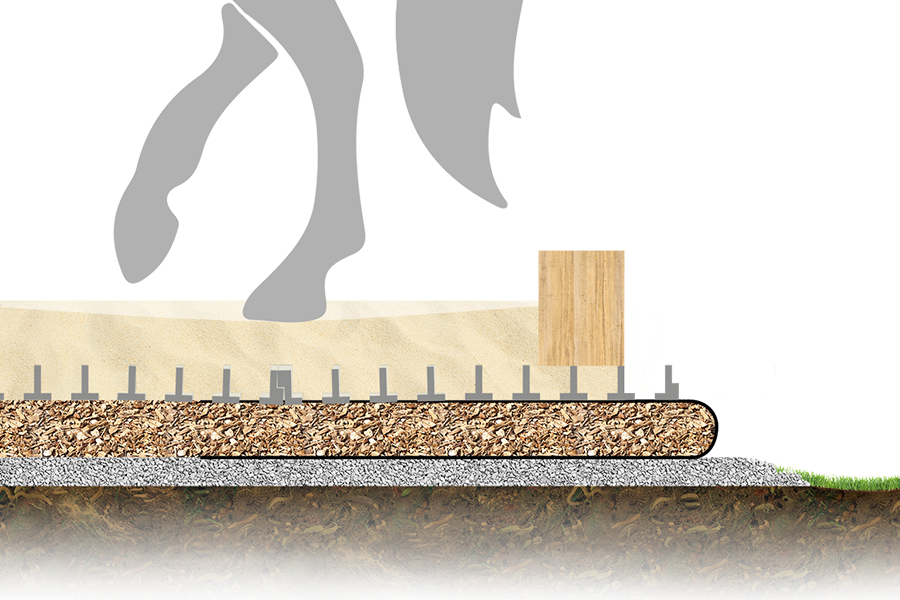

TTE® RIDING ARENAELASTIC

With the TTE® RIDING ARENAELASTIC construction method, an elastic wood layer made of wood chips ensures ideal riding characteristics.

Joint protection

- Optimal shock absorption and energy recovery due to resilient elastic wood layer

- Improved shock absorption in the event of a fall

- Protection of the horse‘s joints, without overloading tendons and ligaments

Befeuchtung

- Re-moistening of the tread layer due to the water storage capacity of the elastic wood layer

- Saving on watering costs

- Protection of the horses‘ respiratory tract and lungs

Frost protection

- Heat generation by macro- and microorganisms in wood and topsoil

- Insulating effect of the wood chips

- Faster thawing of ice and snow

Ideal for leased land and nature reserve areas

- Simpler approval, as hardly any foreign material is introduced

- Residue-free dismantling possible

PLUS alle features of the TTE® RIDING ARENA construction principle

No worries about the wood!

The wood chips of the elastic wood layer rot over the years - but at a much slower rate due to the stored moisture and the exclusion of oxygen. The raw fibre remains intact and continues to guarantee the high evenness, shock absorption and water permeability. The elastic wood layer does not need to be replaced.

Over 20 years of satisfied customers confirm this natural construction method.

The wood chips of the elastic wood layer rot over the years - but at a much slower rate due to the stored moisture and the exclusion of oxygen. The raw fibre remains intact and continues to guarantee the high evenness, shock absorption and water permeability. The elastic wood layer does not need to be replaced.

Over 20 years of satisfied customers confirm this natural construction method.

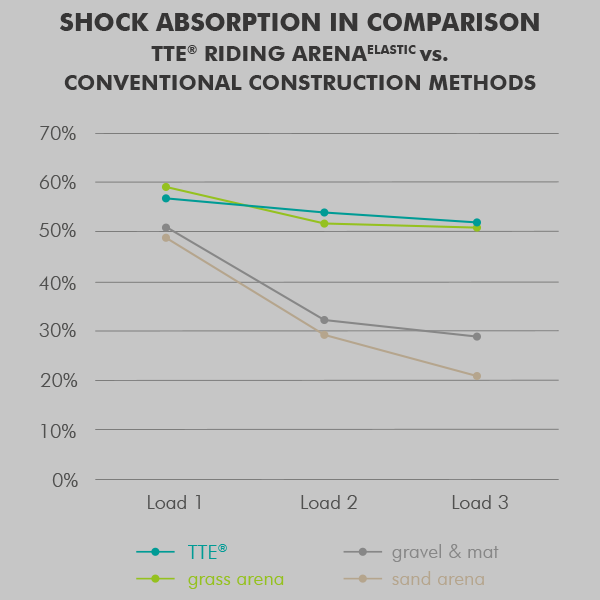

Grass-like riding

TTE® RIDING ARENAELASTIC

The Osnabrück University of Applied Sciences has compared the TTE® construction

with conventional construction methods in terms of shock absorption.

TTE® RIDING ARENAELASTIC arenas thus perform ideal values of power decay and energy recovery under recurring loads, which correspond to a grass arena under ideal conditions.

Experience shock absorption at a high level with constant performance!

with conventional construction methods in terms of shock absorption.

TTE® RIDING ARENAELASTIC arenas thus perform ideal values of power decay and energy recovery under recurring loads, which correspond to a grass arena under ideal conditions.

Experience shock absorption at a high level with constant performance!

Advantages of the TTE® RIDING ARENA

construction principle

The quality savings package

- Constantly high riding comfort

- Usable in all weather

- Simple & rapid installation (DIY possible)

- Without substructure: cost and material savings

- TTE® RIDING ARENAELASTIC: one single solution for show jumping and dressage

Riding that is gentle on the joints

- Areal elasticity for long-term joint protection with TTE® RIDING ARENAELASTIC

- Relieves strain on horses’ tendons and ligaments

Landscape protection concept

- Easy to receive approval

- Original surface is carefully built over and preserved

- Does not disturb the living soil zone

- Groundwater protection